30 Bremer Road Murray Bridge SA 5253 Australia ABN 54 737 375 522

ROGER WEICHERT ELECTRONICS Mob: 0400 226839

incorporating ... boumaticboardrepairs.com.au

www.dairycircuitboardrepairs.com.au

Just some of the

boards we fix.

3200 Boumatic Detachers

-------------------------

3400 Perfection

Boumatic Detachers

-------------------------

4600 Signature Series

Boumatic Detachers

-------------------------

Boumatic PC-201

Pulsation Controllers

-------------------------

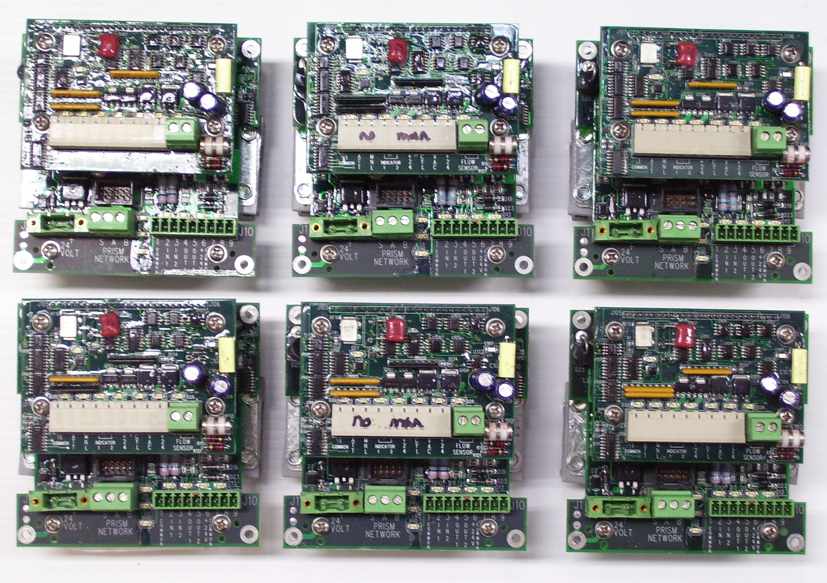

Boumatic PRISM

Pulsation Controllers

-------------------------

Boumatic

Glacier-Guard

and

Guardian II

Control Boards

-------------------------

Waikato MultiPhase

System

-------------------------

DeLaval

'Alpro' MPCII

-------------------------

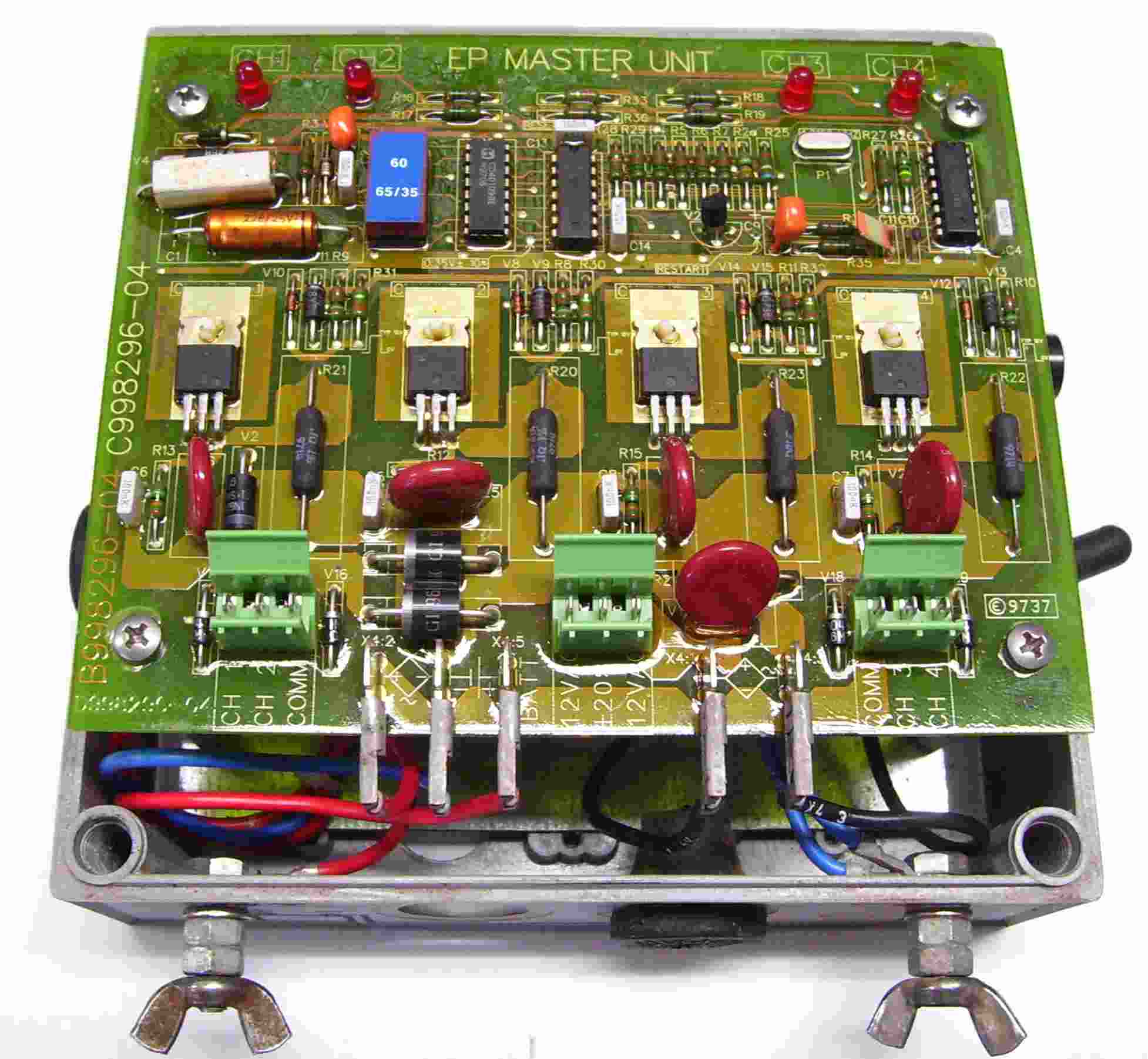

DeLaval

EP Master Units

-------------------------

DairyKing / DairyMaster 2028

Pulsation Control Boards

-------------------------

For All Dairy Farmers & Dairy Service Technicians ...

Dont Spend $1000's Replacing Faulty Electronics In Your Dairy ... Until You've Read These Pages

Boumatic

As you can read on our ‘About Us’ page ... Boumatic 4600

Signature Series Detachers

... or ‘automatic cup remover’ boards ...

were

where we first started with dairy circuit board repairs.

Signature Series Detachers

... or ‘automatic cup remover’ boards ...

were

where we first started with dairy circuit board repairs.Having focused on them for a number of years ... we've now became inundated with other models from Boumatic's range ... as well as many other brands.

Detachers

ParlorMetrix Detachers

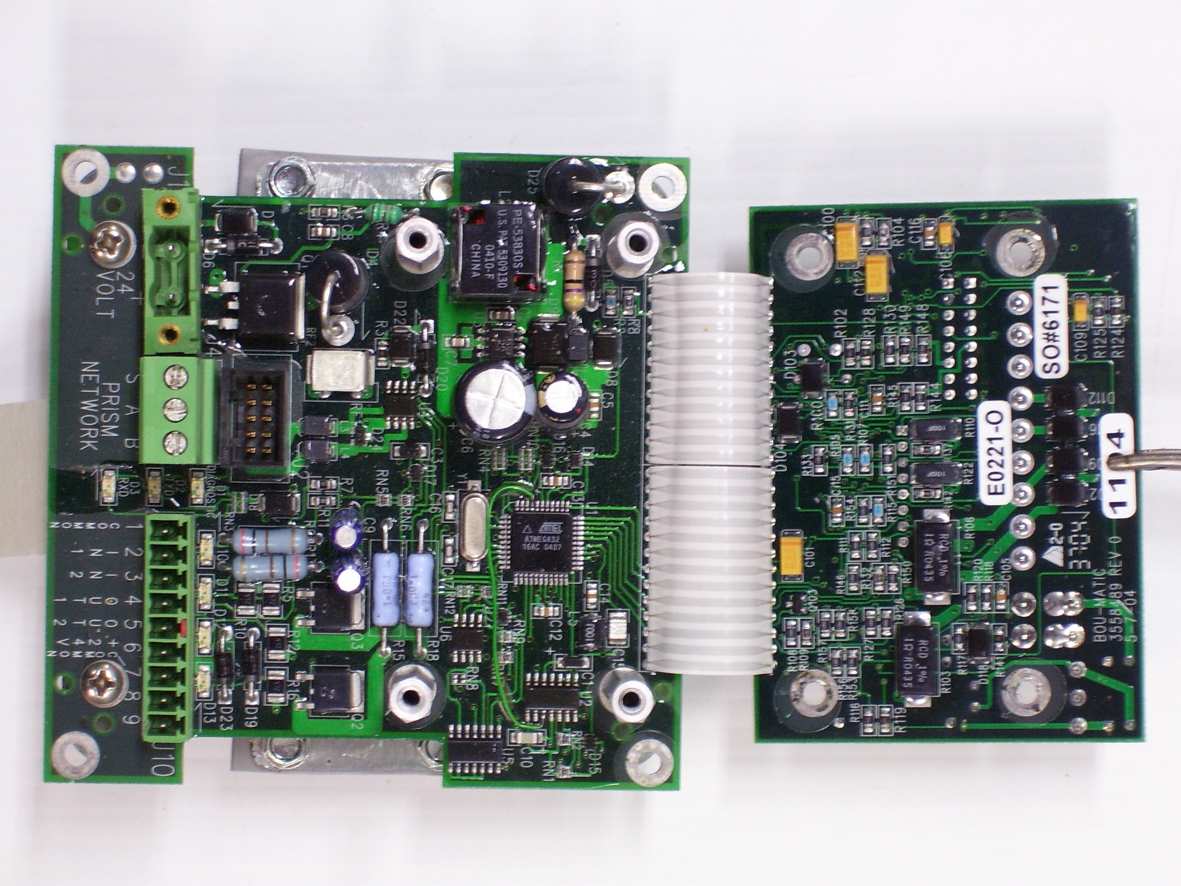

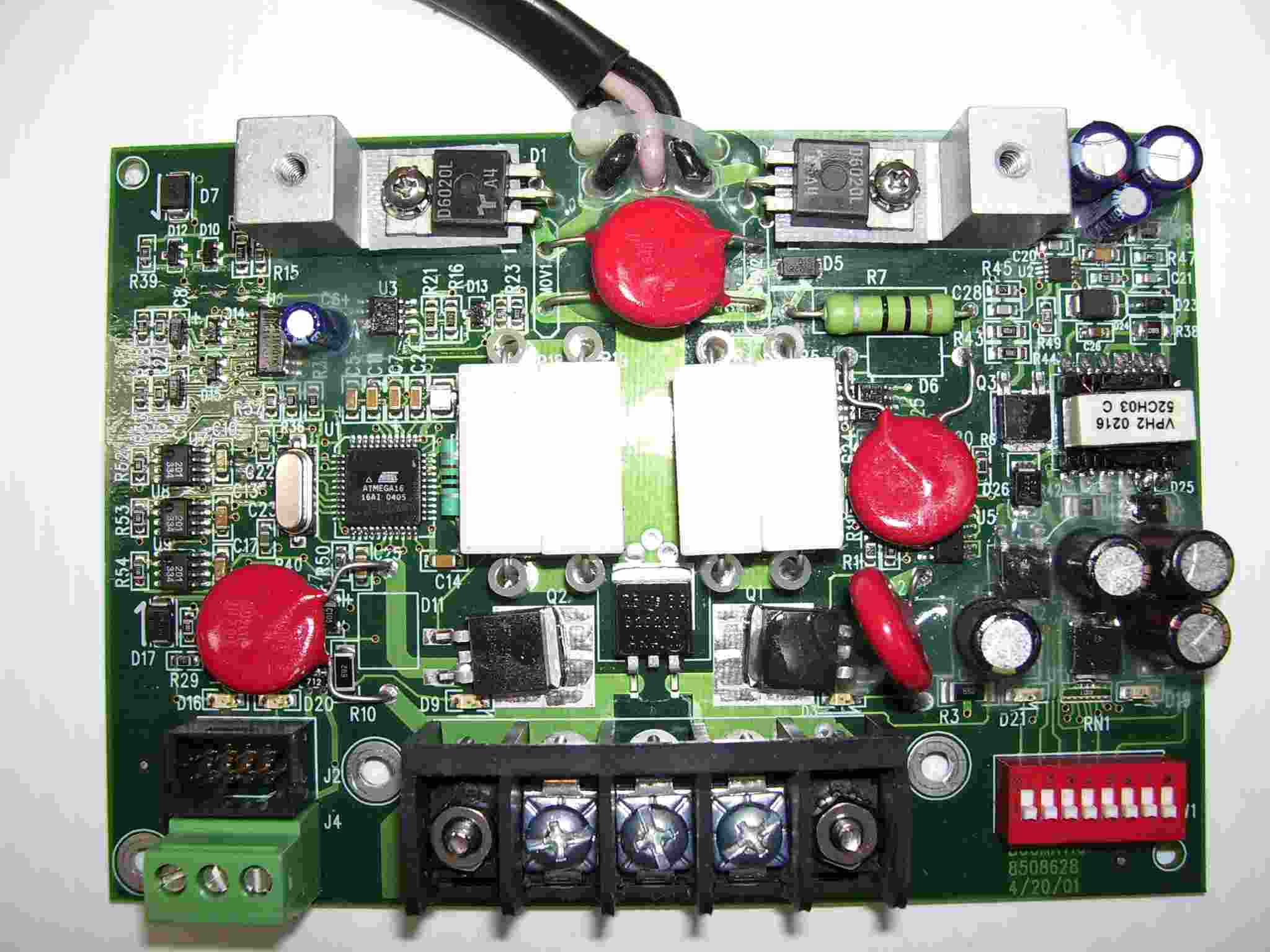

These are the latest of the Boumatic boards we've been asked to repair ... the ParlorMetrix detacher units.

ParlorMetrix detachers consist of two boards permanently connected and sandwiched together on a small metal frame ... there's one needed for each milking point

ParlorMetrix detachers form a fairly sophisticated system that monitor the milking process ... operator and equipment wise ... and in the words of Boumatic's marketing people, are a ... " performance-monitoring network of detachers that transmit data to a PC to provide information that can be used to maximise parlor productivity and profitability"

Download pdf brochure here ...

One way they do this is through some fairly unique bar graphs and charts generated for each milking, to show at a glance how well the session went.

This then enables fine tuning of procedures and detacher settings etc. to get the best out of the milkers, the cows and the dairy.

Another feature is the fact that the system has been designed for the detachers to be mounted remotely to each milking point, ie in a well sealed box in an adjacent room to the main dairy ... which protects them enormously from the hostile environment that detachers normally operate in.

Despite all this, electronics being electronics, a certain percentage are still going to break down.

That is where we can help, and can save you a substantial amount of money and aggravation over buying replacements.

Contact us if you have any questions about fixing any of these boards.

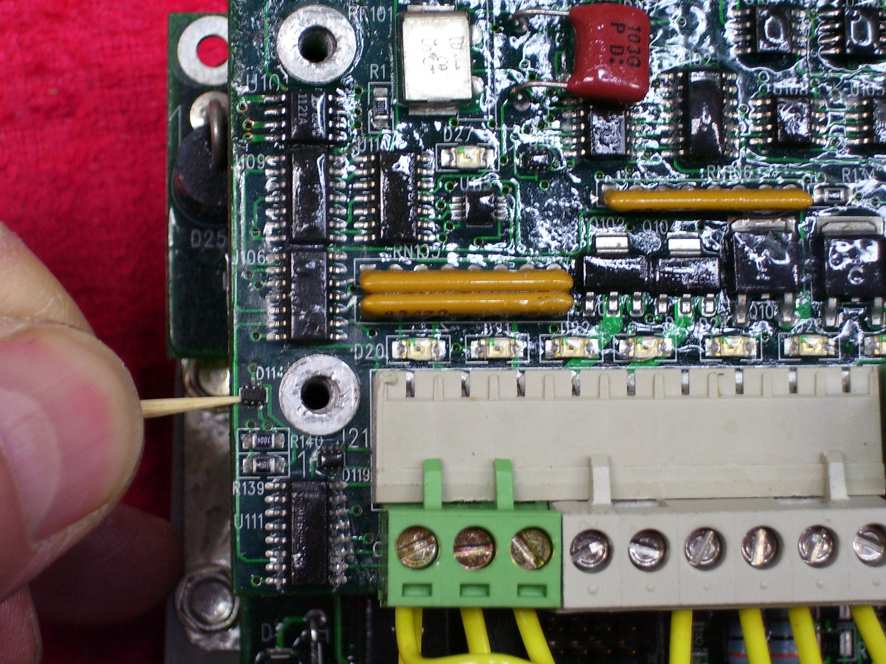

Components are getting smaller and smaller ... despite it's tiny size, the diode array at the end of this tooth pick, has six legs.

This one 'fell' off as we attempted to connect to it to measure it's operation ... try stitching one of these little suckers back on if you want to check your eyesight or your soldering skills !!!

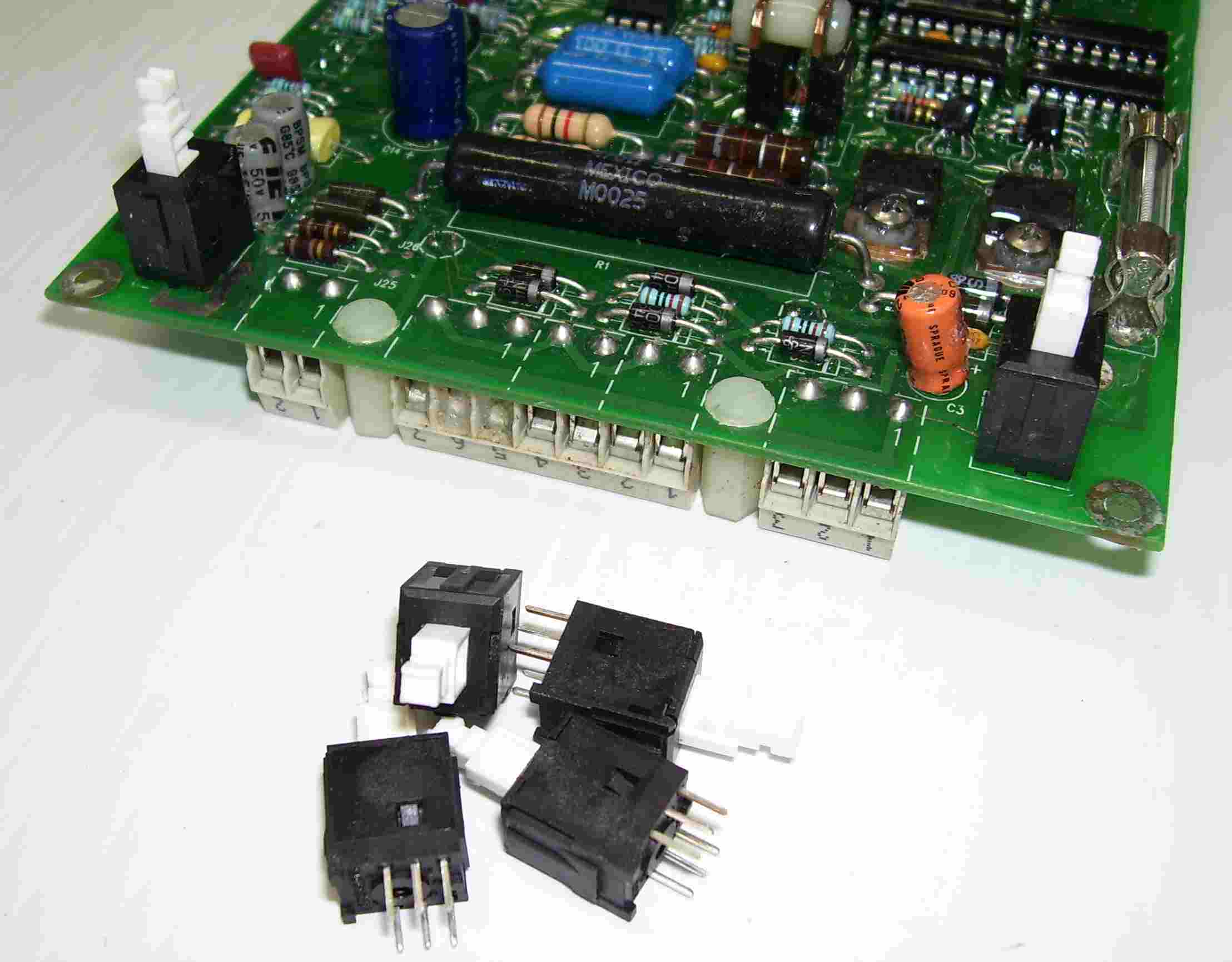

The 3200 Series Detachers

- Have you been having trouble with the switches on your 3200 detachers?

- Water getting in and rusting them out?

- Don’t really want to spend big money fitting stainless steel ‘piezo’ switches?

Well ... we can replace them with genuine switches ... the same as the originals ... which will give new life to your boards.

... and an advantage (over stainless switches) ... is that each detacher can still be ‘reset’ from the front panel ... rather than having to get in to disconnect the power, every time a reset is needed.

If you have one or more faulty boards ... contact us ... we’ll organise a time that suits us both ... then send in the boards for a prompt repair and quick turn-around time.

If there is a possibility you may be interested in fitting stainless switches some time in the future ... we also fit flyleads to the board at the same time ... so that you can fit the switches yourself any time you choose ... without having to send the boards off again ... and I’m sure more importantly for you ... not having to take them out of the dairy again..

If for some reason you’d rather not have these flyleads fitted ... please mention that when organising the work to be done.

For those of you who don’t know what is involved in fitting the stainless piezo switches ... it entails (once the above mentioned flyleads are added) ...

... removing the front cover

... carefully pulling the shaft out of the pcb switches with a pair of pliers

... fitting the new switches in place of the original buttons

... then hooking up the wires from the new switches to the flylead connectors mentioned above

Really quite simple ...

Also, we should add too ... that obviously other faults can occur on these boards as well ... so it’s not always the switches. Feel free to contact us if you have any questions about these boards.

If you are sending in any of these boards ... please download and print out a Repair Form ... fill it in ... and send it with your boards. It provides us with information about the symptons of the fault you're seeing ... shipping ... and your preferred payment method.

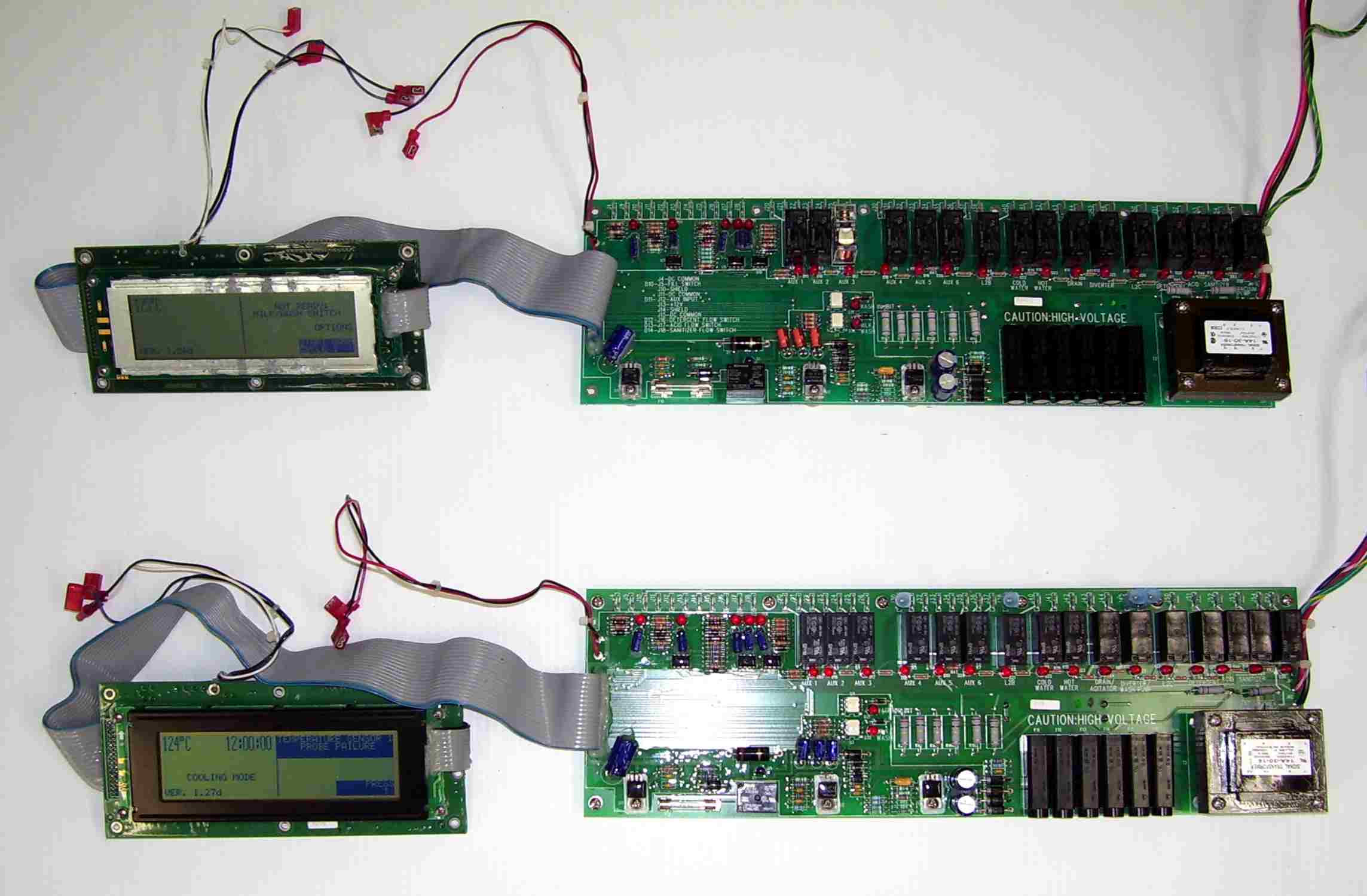

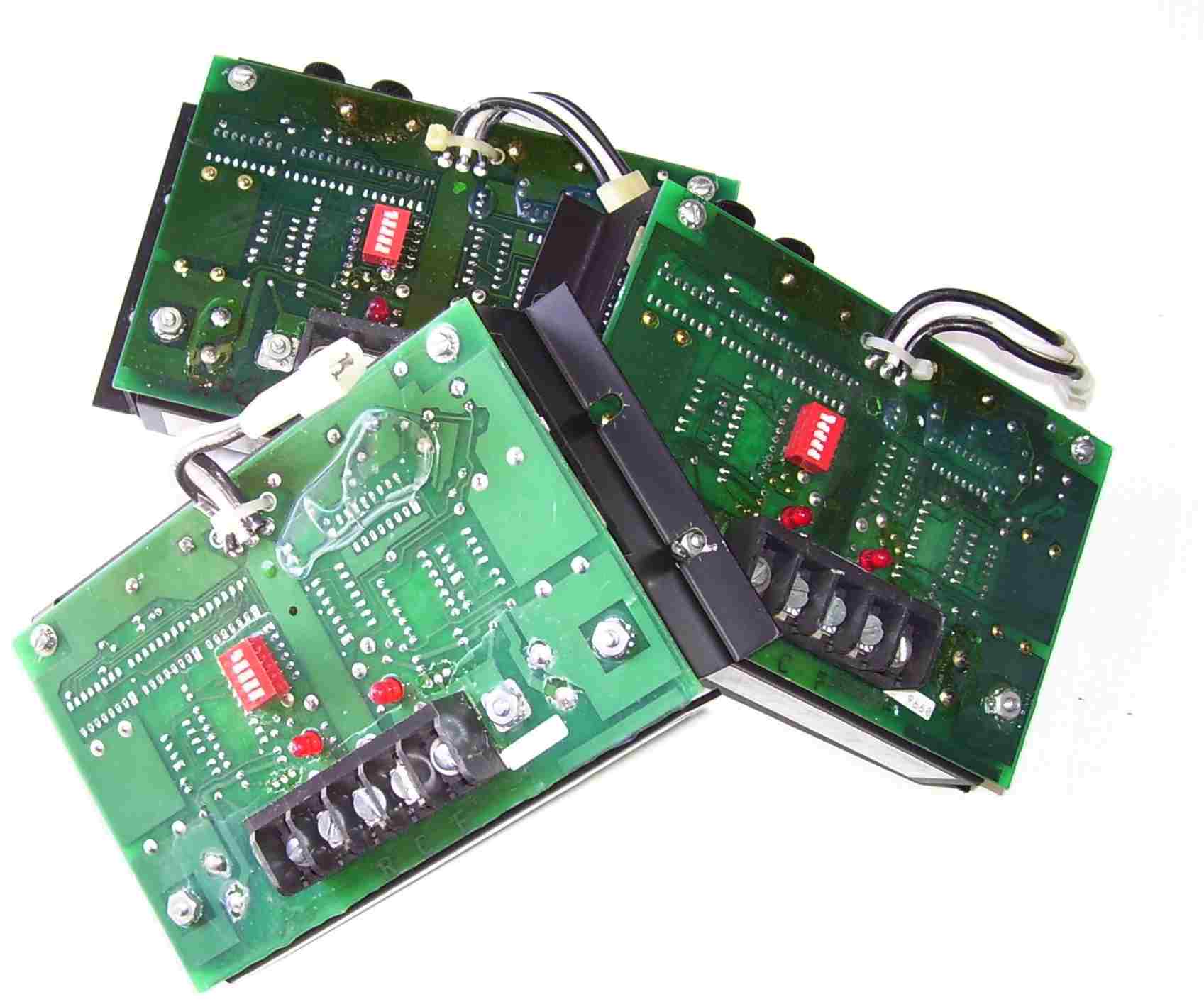

Another batch of 3200 Detachers with new switches

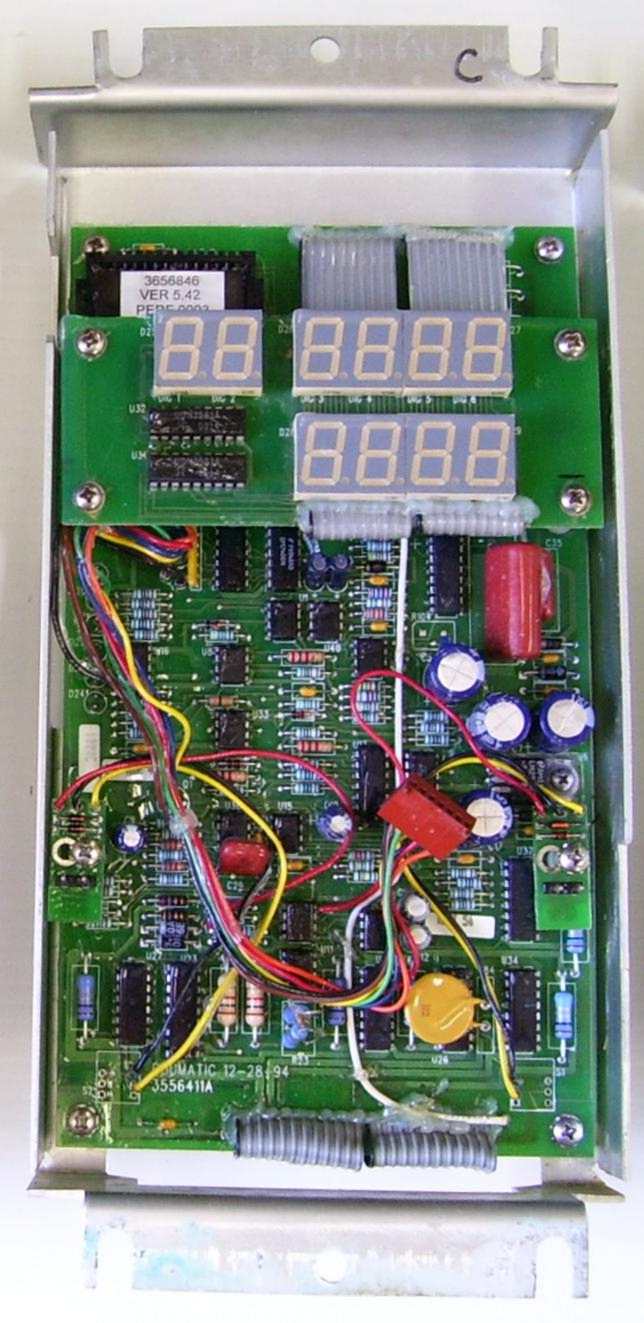

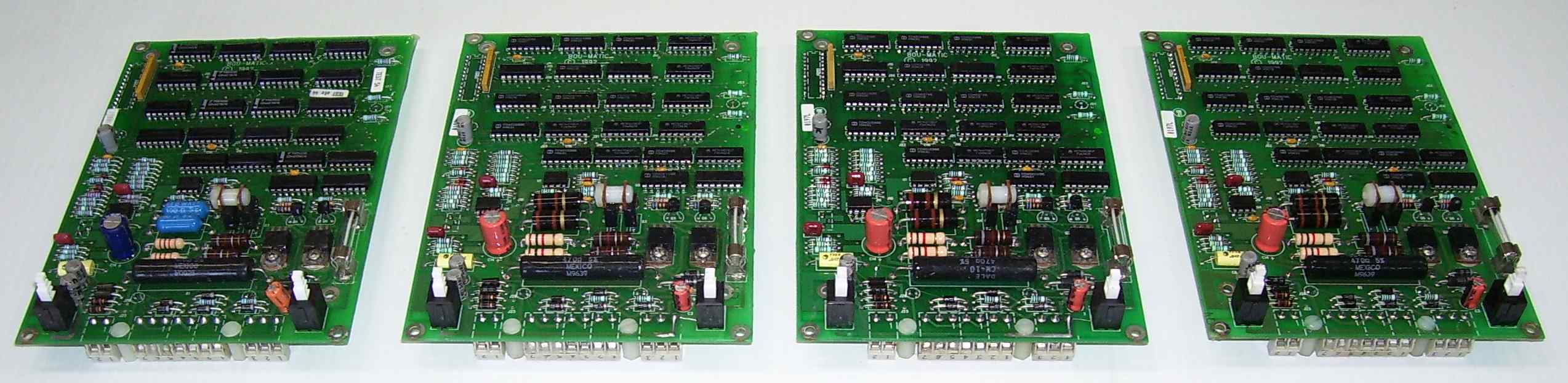

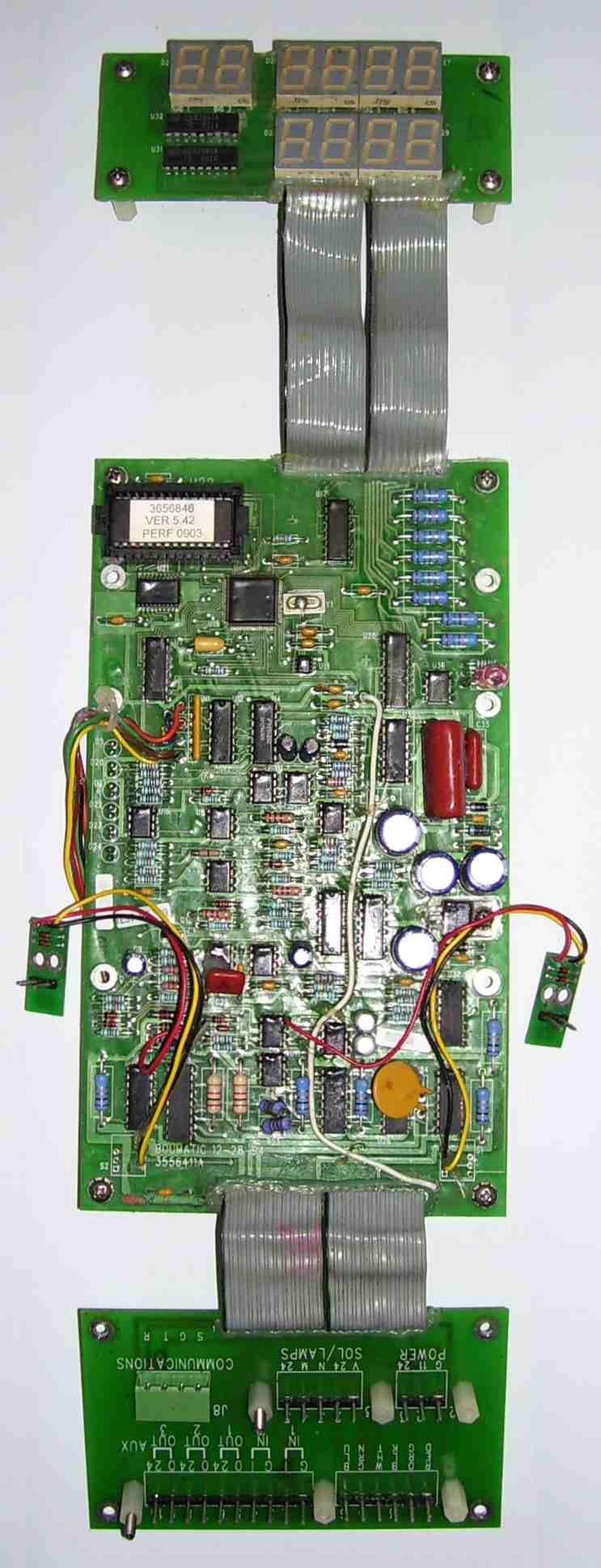

3400 Perfection Milk Meter Detachers

These are more sophisticated again ...

than the 3200 series detachers.

These are more sophisticated again ...

than the 3200 series detachers.They include quite a bit more intelligence ... along with digital displays to provide data at each milking bay ... as well as a communications channel to and from the computer back in the office.

As with most dairy equipment ... moisture is probably the biggest killer for these boards. It then depends on where that moisture ‘sits’ and where the moisture protection barrier is weakest or has broken down ... as to what fails ... and what symptons you will have.

We have seen everything from plain corrosion ... of tracks and leads ... failed seven-segment displays ... faulty IC’s ... through to failed microprocessors.

So far most have been repairable ... so don’t write yours off yet.

It's hard to give a firm price for repair up front ... it depends on where the damage is ... as to what the end cost will be.

Obviously ... replacing an 80 pin surface-mount microprocessor ... or all twelve seven-segment displays, is more time consuming and expensive ... parts wise ... than a simple corrosion repair job.

If you are sending in any of these boards ... please download and print out a Repair Form ... fill it in ... and send it in with your boards. It provides us with information about the symptons of the fault you are seeing with the board ... and shipping and payment options.

Some more 3400 detachers

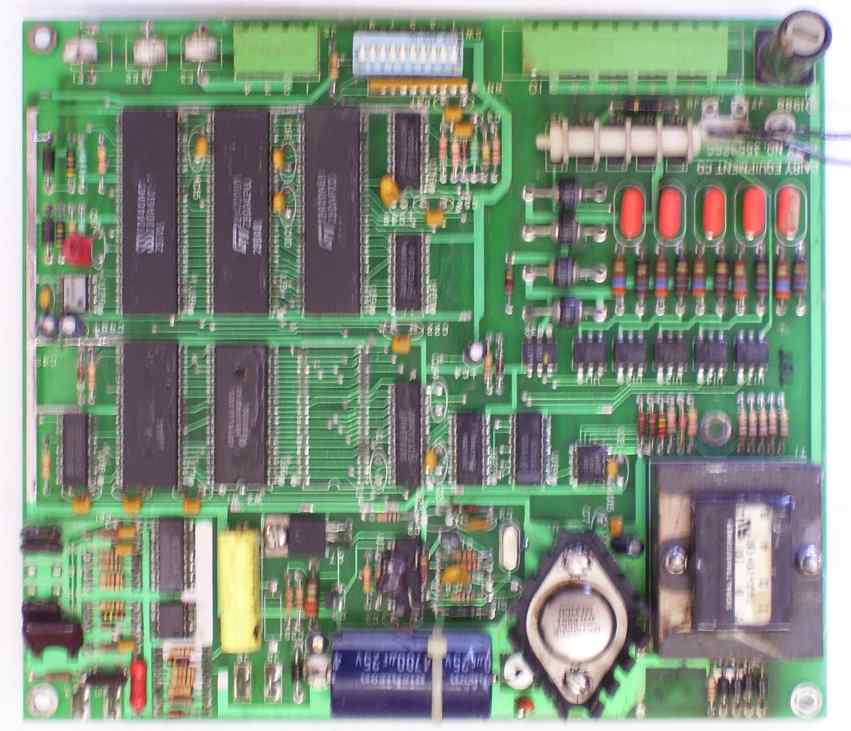

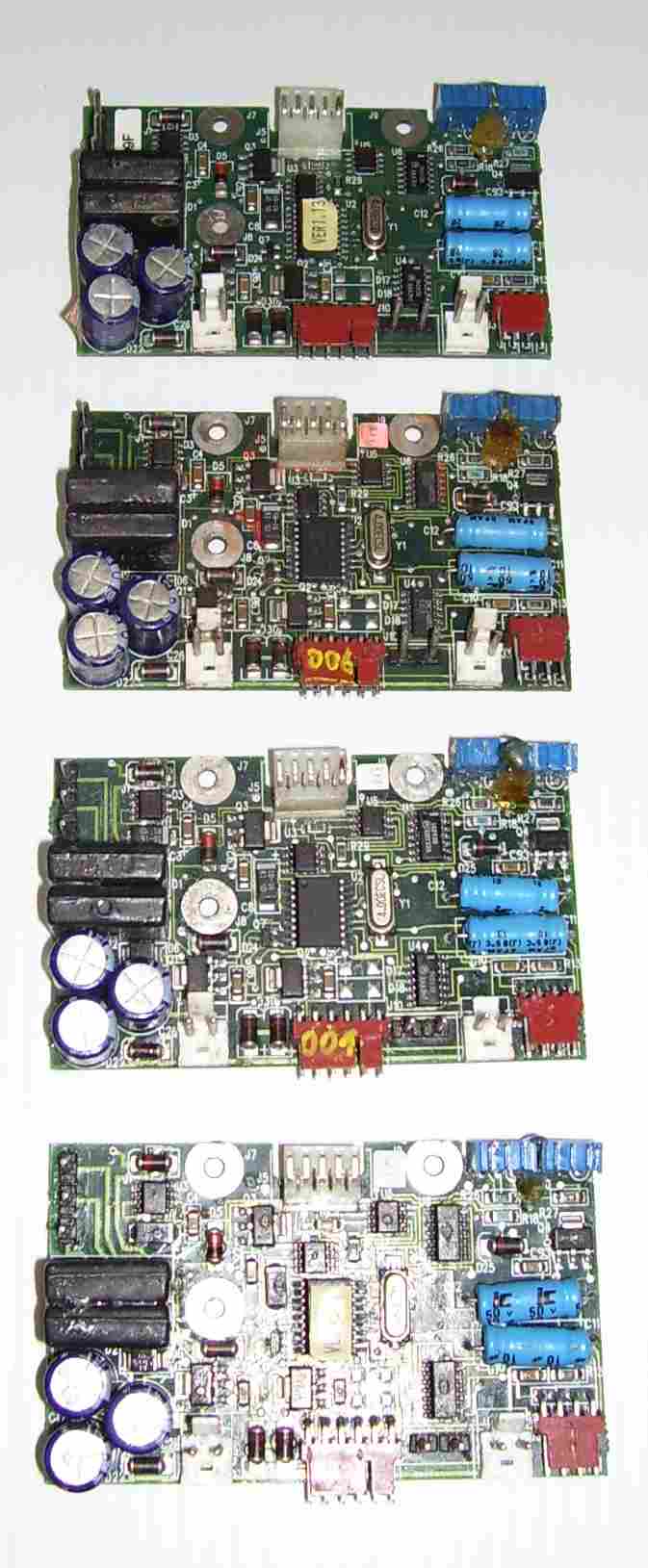

4600 Signature Series Detachers

As mentioned above, these boards are the ones we cut our teeth on ... and again ... moisture seems to be the main cause of their problems.

The sort of faults we see are ... corrosion of tracks and connectors ... faulty pots ... blown surface mount led’s, mosfets and IC’s ... and also the occasional ‘misfiring’ or dead microprocessor.

We keep a full series of parts for these boards ... so most faults are fixable. Our main weapon is a sophisticated test jig that we designed and built to put the boards through their paces ... initially to find faults ... and then to test them thoroughly after repair.

If you are sending in any of these boards ... please download and print out a Repair Form ... fill it in ... and attach it to your boards. It provides details of the fault you're seeing ... and shipping and payment details.

If you'd like us to program the boards with your settings before we send them back ... please download and fill in this form also.

Feel free to contact us with any questions you may have.

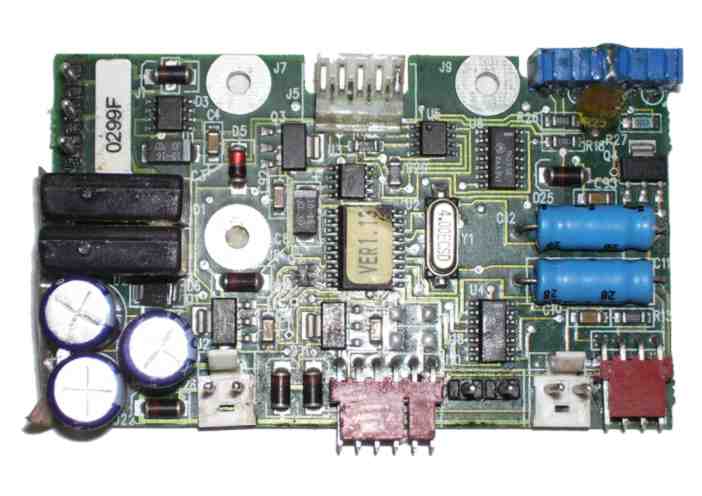

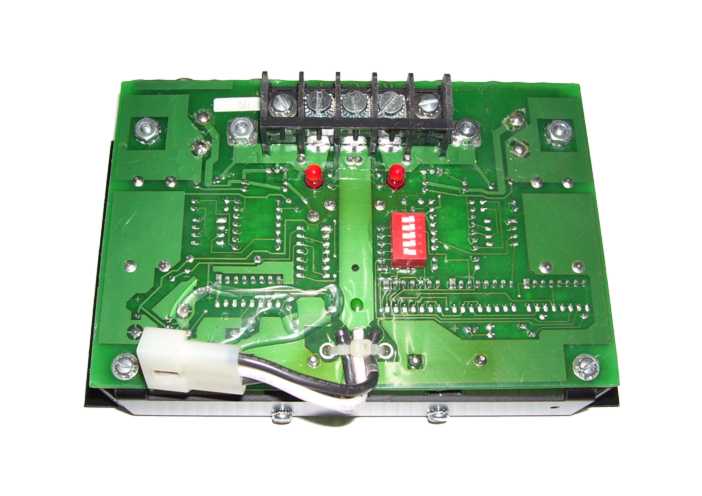

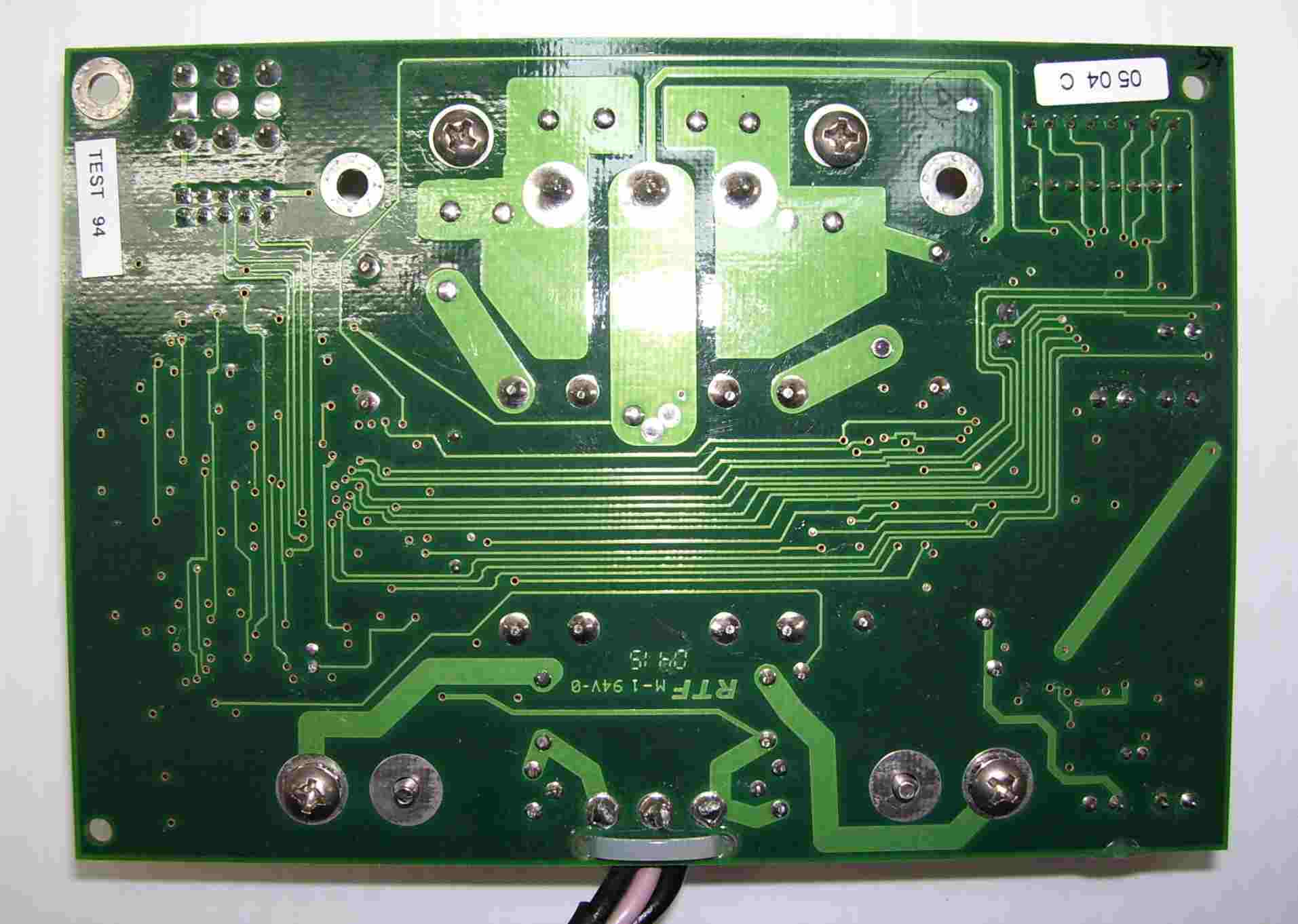

4600 Detacher ... front and rear views

Pulsation Controllers

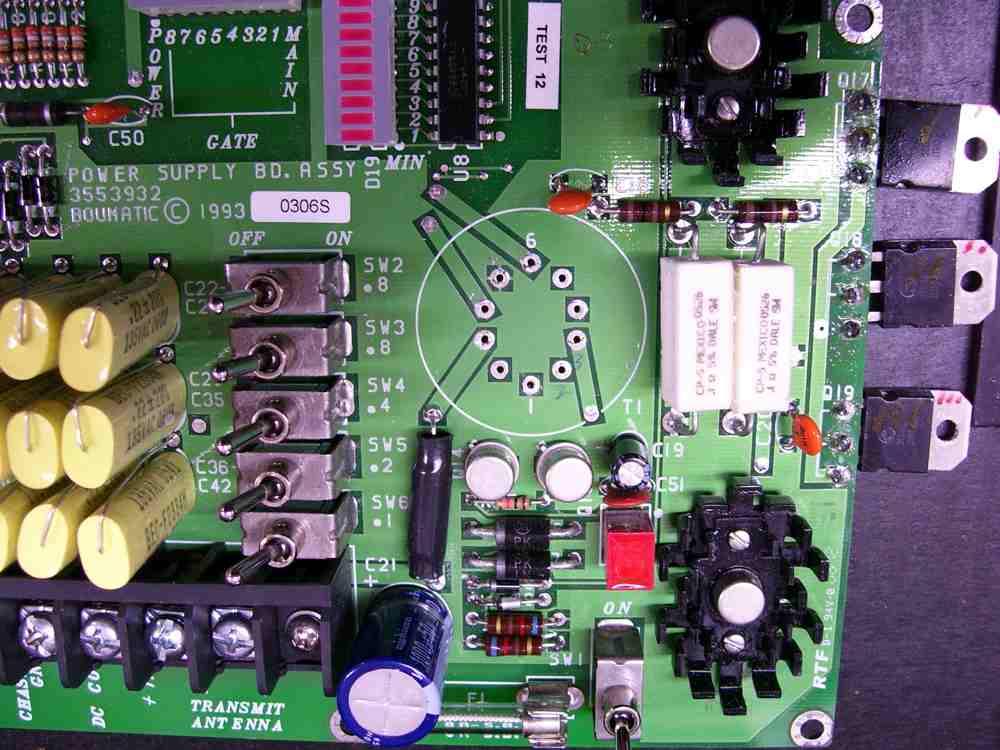

PC-201 Pulsation Controller

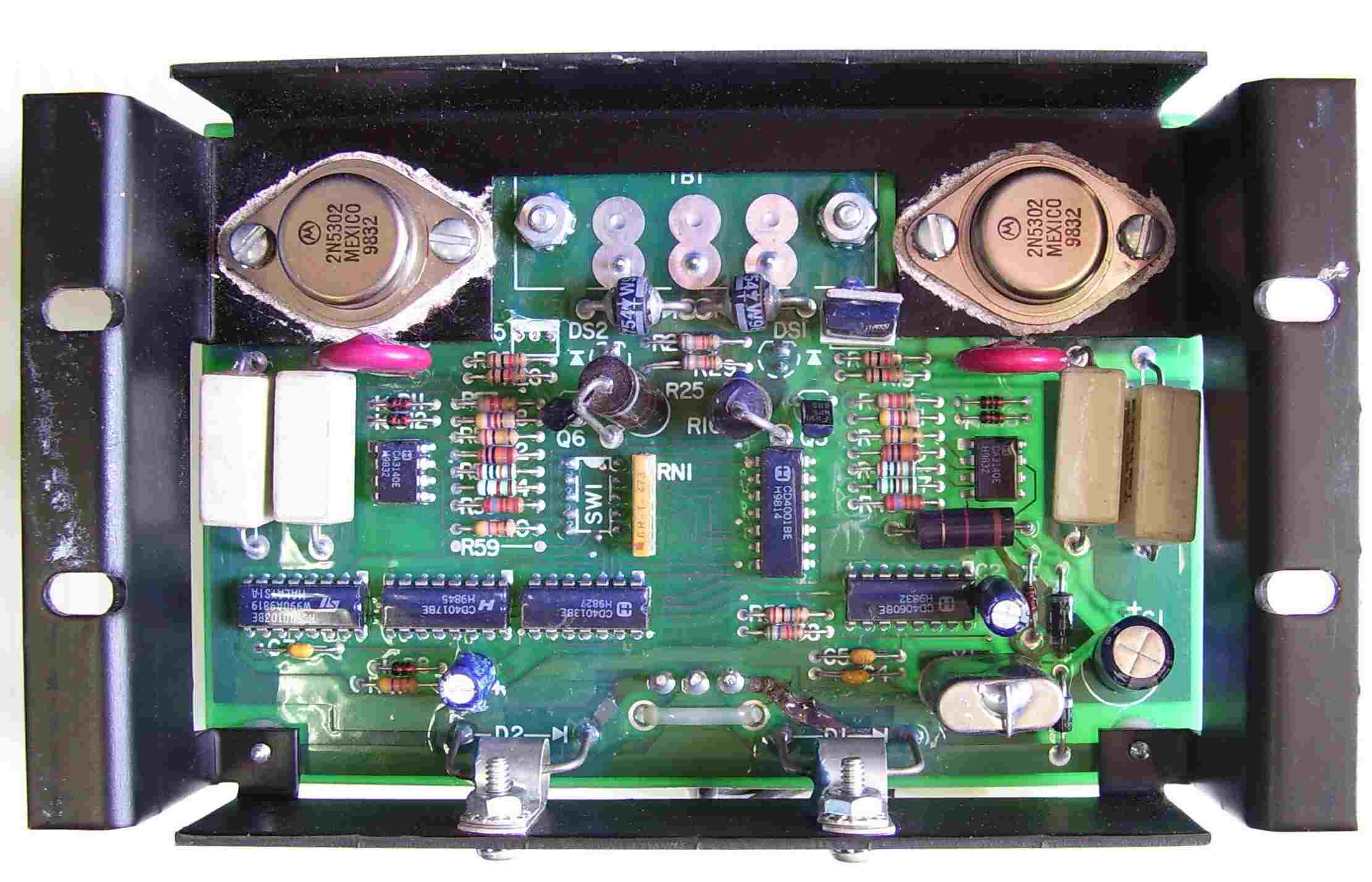

These older boards do an amazing amount of work over their lives ... so it is not surprising to see them fail occasionally.

Having said that ... on most of the ones we see ... the faults are caused by wiring or external factors ... not by any inherent weakness of the board itself.

Most times the repair entails replacing the power transistors ... supply diodes ... power resistors ... driver transistors, and repairing burnt tracks etc ... then sealing the pcb ... and we also fit a pair of fuseholders to add protection from the external factors mentioned above.

As long as no-one fits fencing wire in place of the fuses ... the additional protection will pay off handsomely if anything major goes wrong externally.

If you are sending in any of these boards ... once again ... please download and print out a Repair Form ... fill it in ... and attach it to your boards. It provides details about the fault ... and details about payment and shipping.

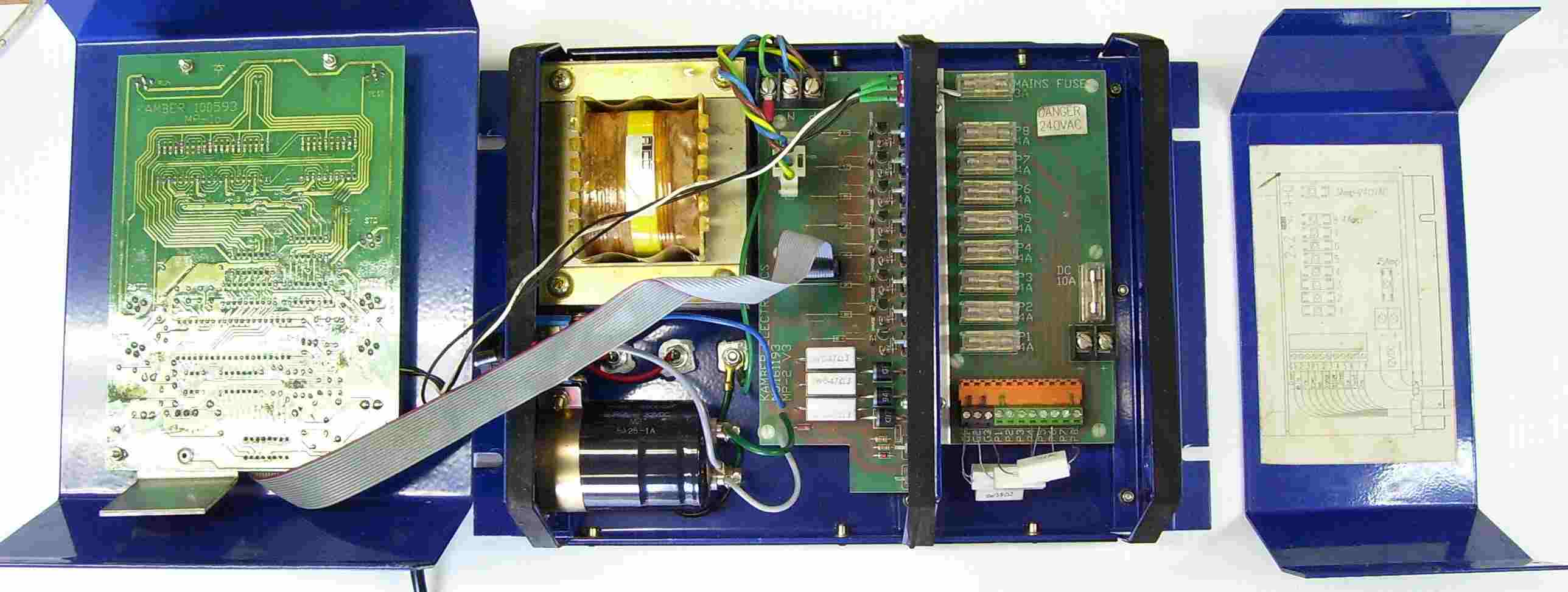

PC-201 Pulsation Controller with Power Supply and Extra Boards

PC-201 ... before ... and after

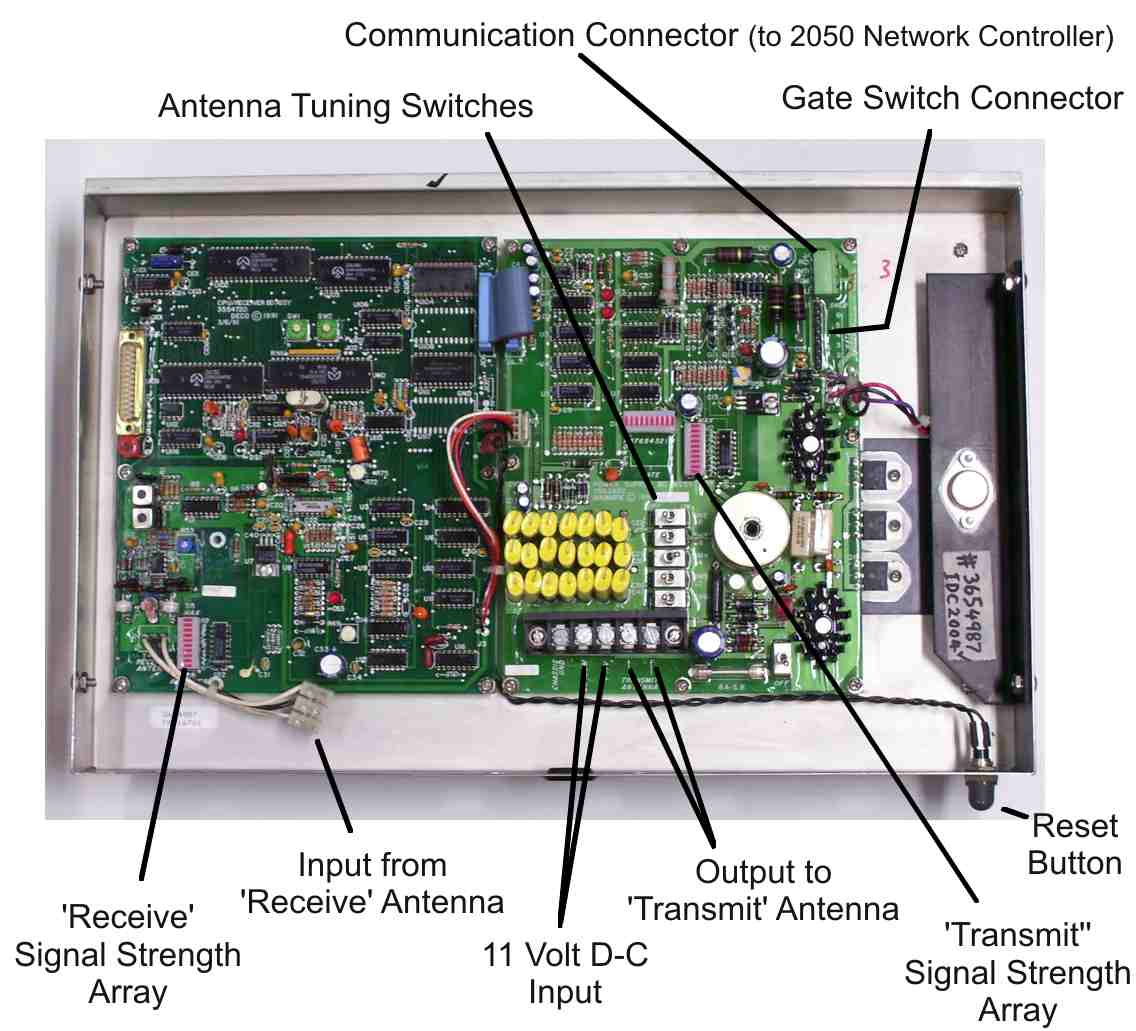

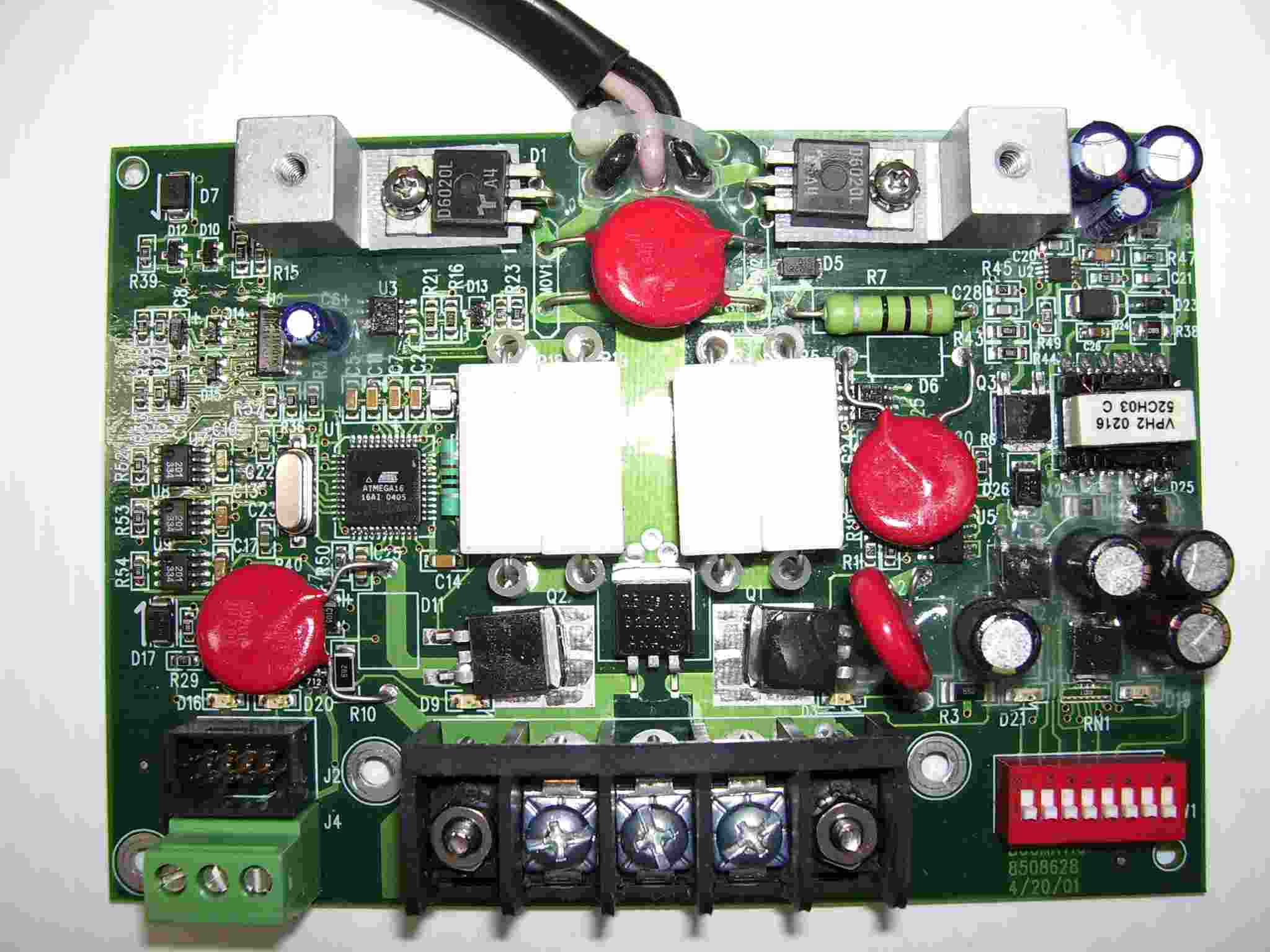

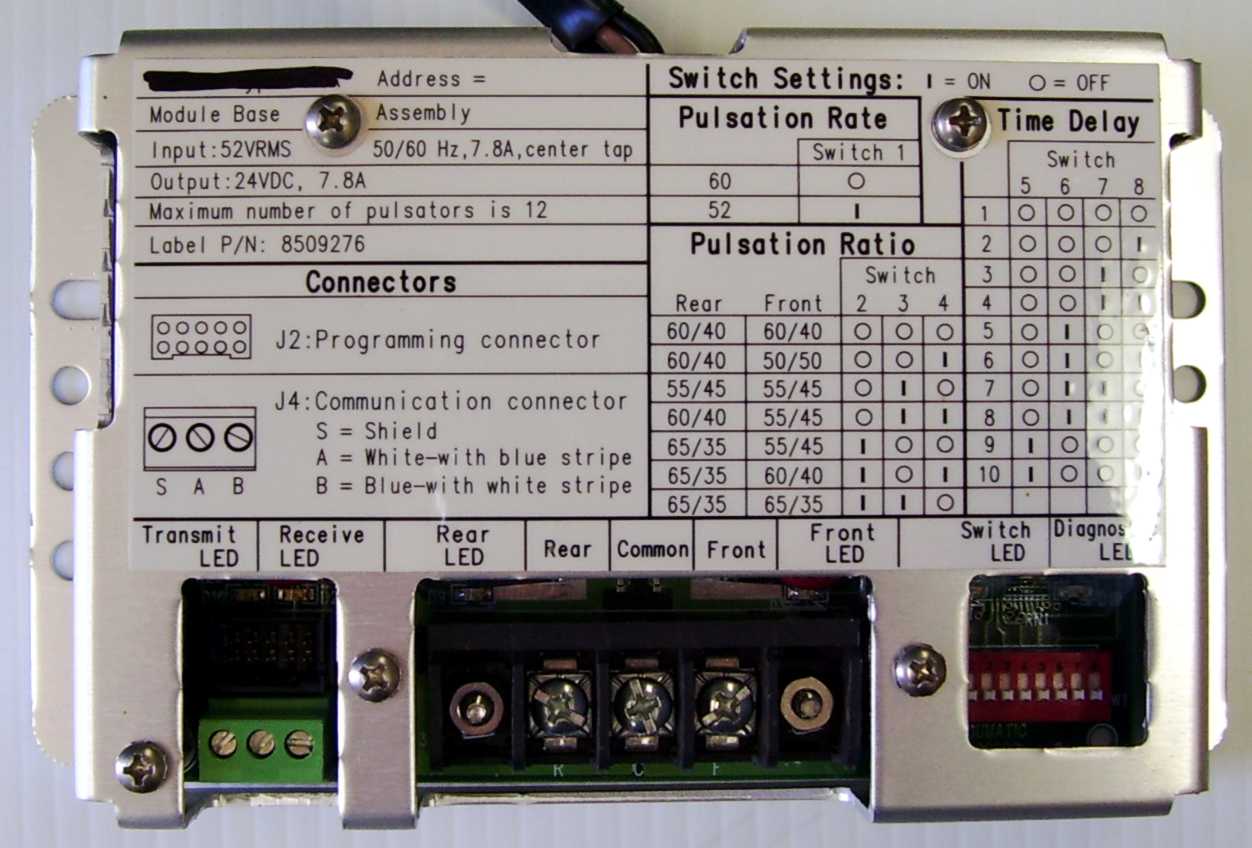

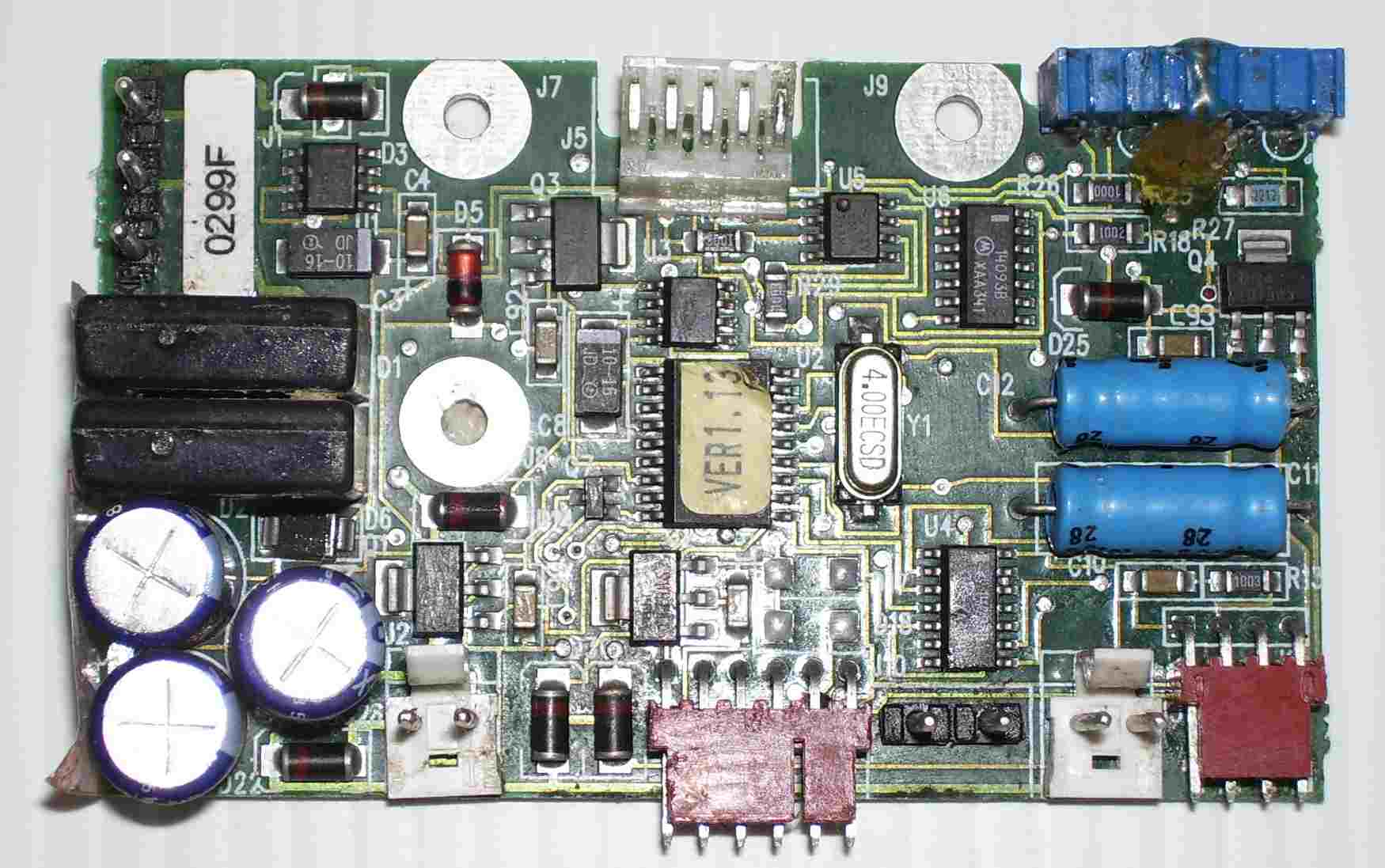

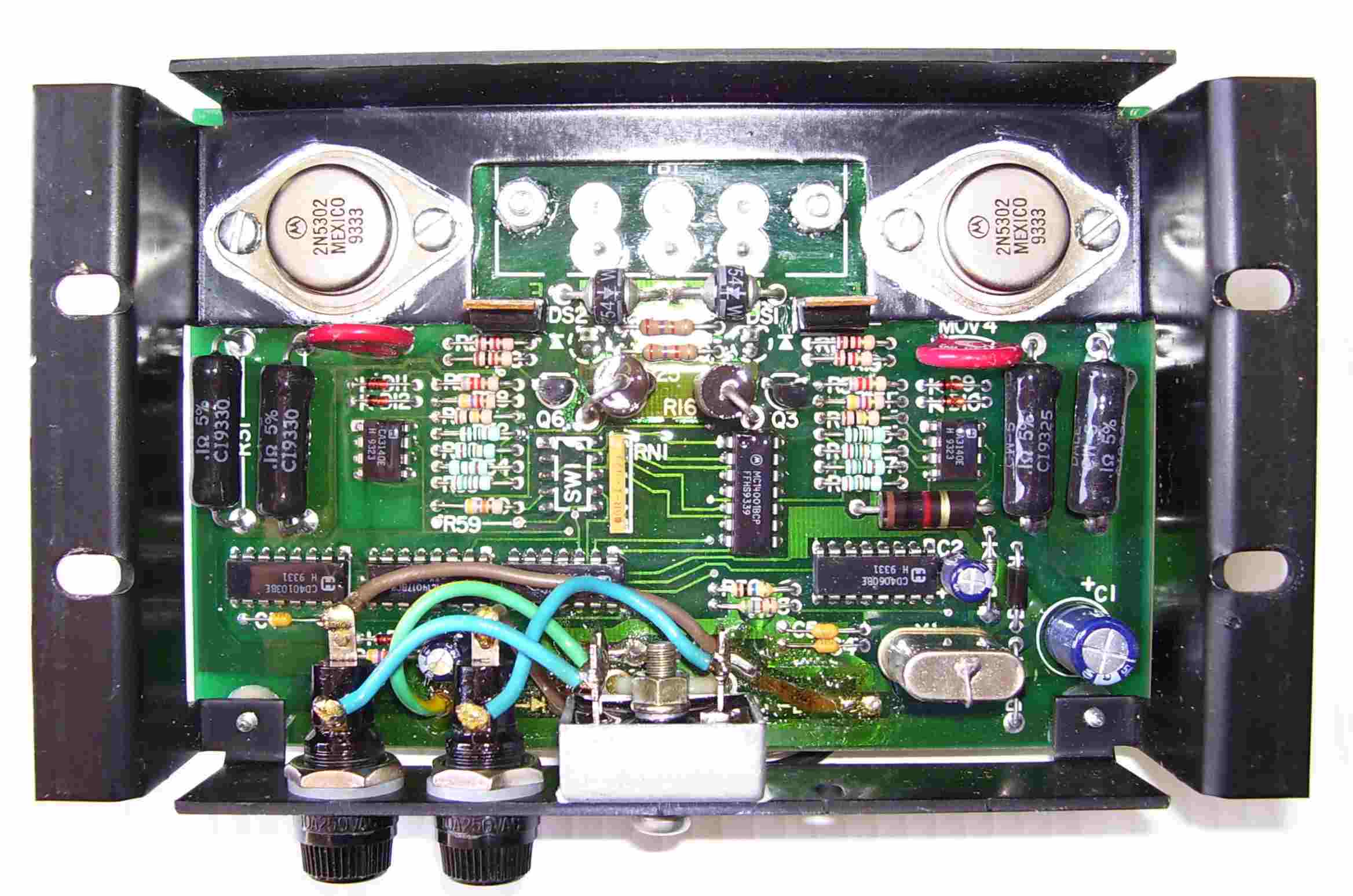

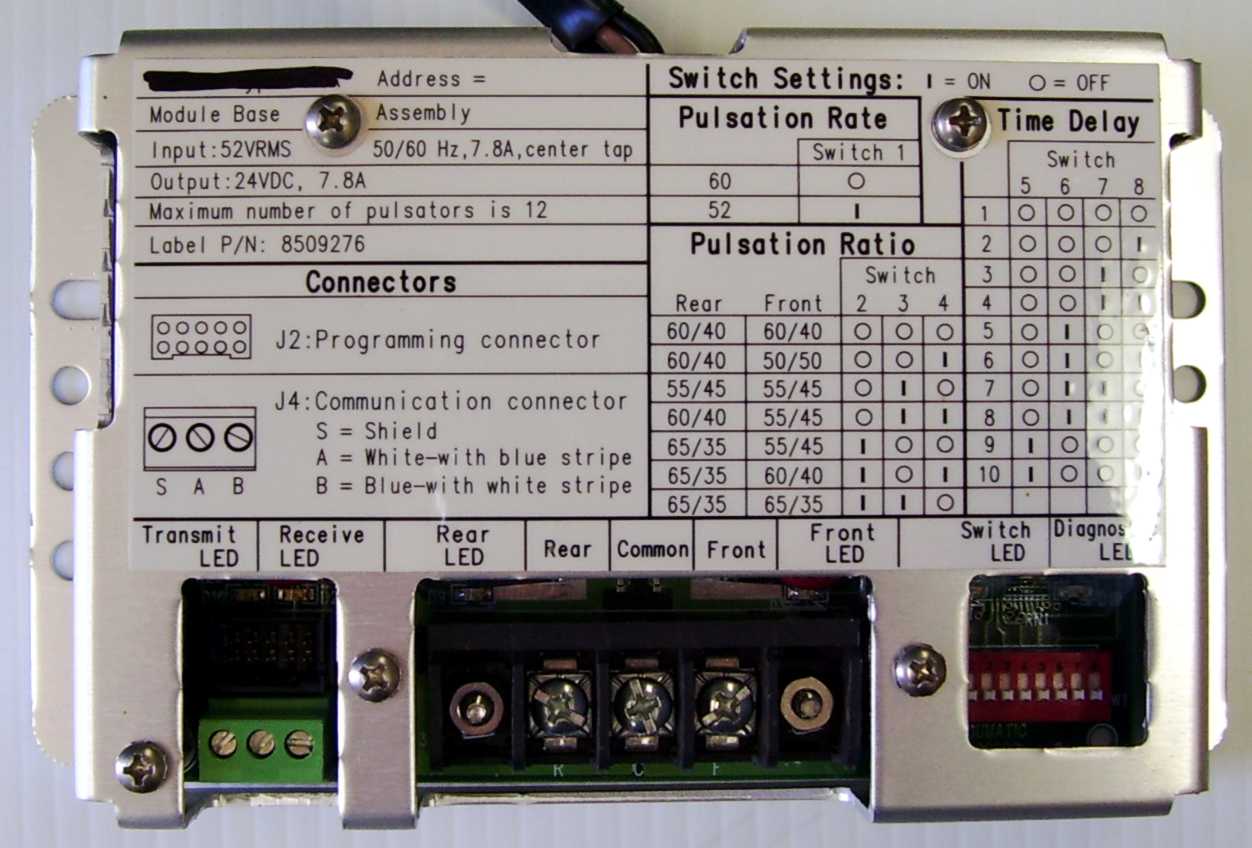

PRISM Pulsation Controller

These newer pulsation control boards are a much more sophisticated update of the PC-201.

They are programmable ... so it pays to go through the diagnostic procedure described in the manual before sending any in ... as often they can be set straight by reprogramming or resetting in place.

The board pulsation rate and ratio can be set either with the onboard DIP switches or via a PC or a Network Controller.

If set via the latter, the settings are retained until reprogrammed .. but note ... the DIP switches will have no effect unless the device is re-programmed to allow it.

If the 'Switch' led is on, the switch settings are adjustable ... but if 'off', the board can only be adjusted by programming.

If you aren’t sure about the troubleshooting procedure or need the instructions ... download them here ... or give us a call and we should be able to help you out.

If you are sending in any of these boards ... please download and print out a Repair Form ... fill it in ... and attach it to your boards. Again ... it provides details for payment, shipping and the fault you are having with the board.

PRISM PCB ... front and rear view

... and back in it's box

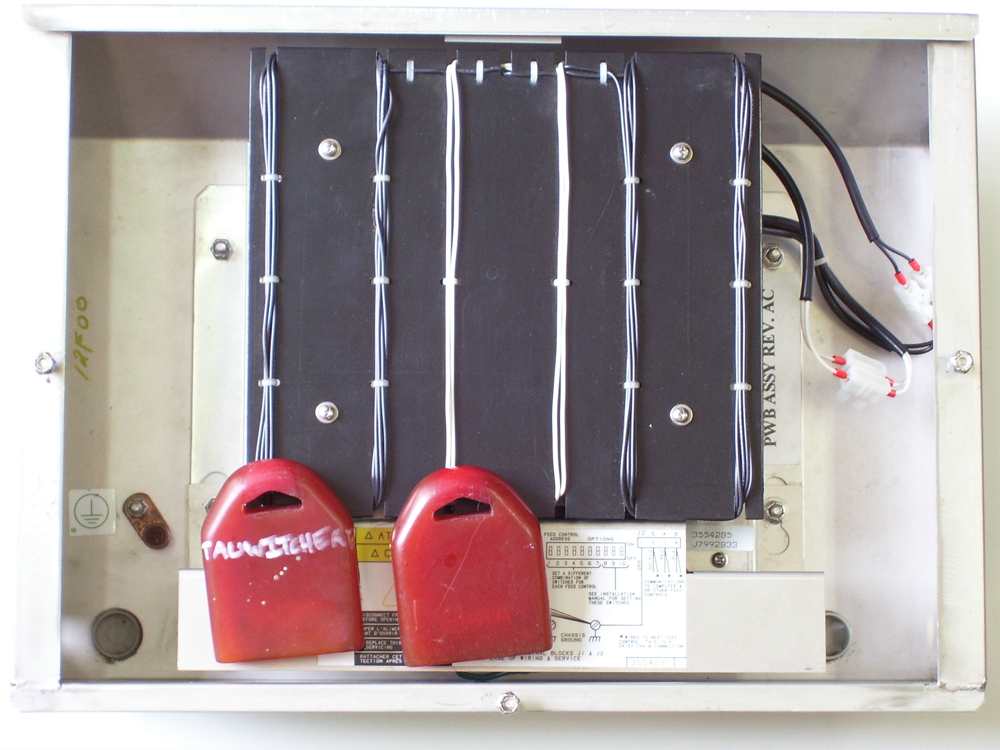

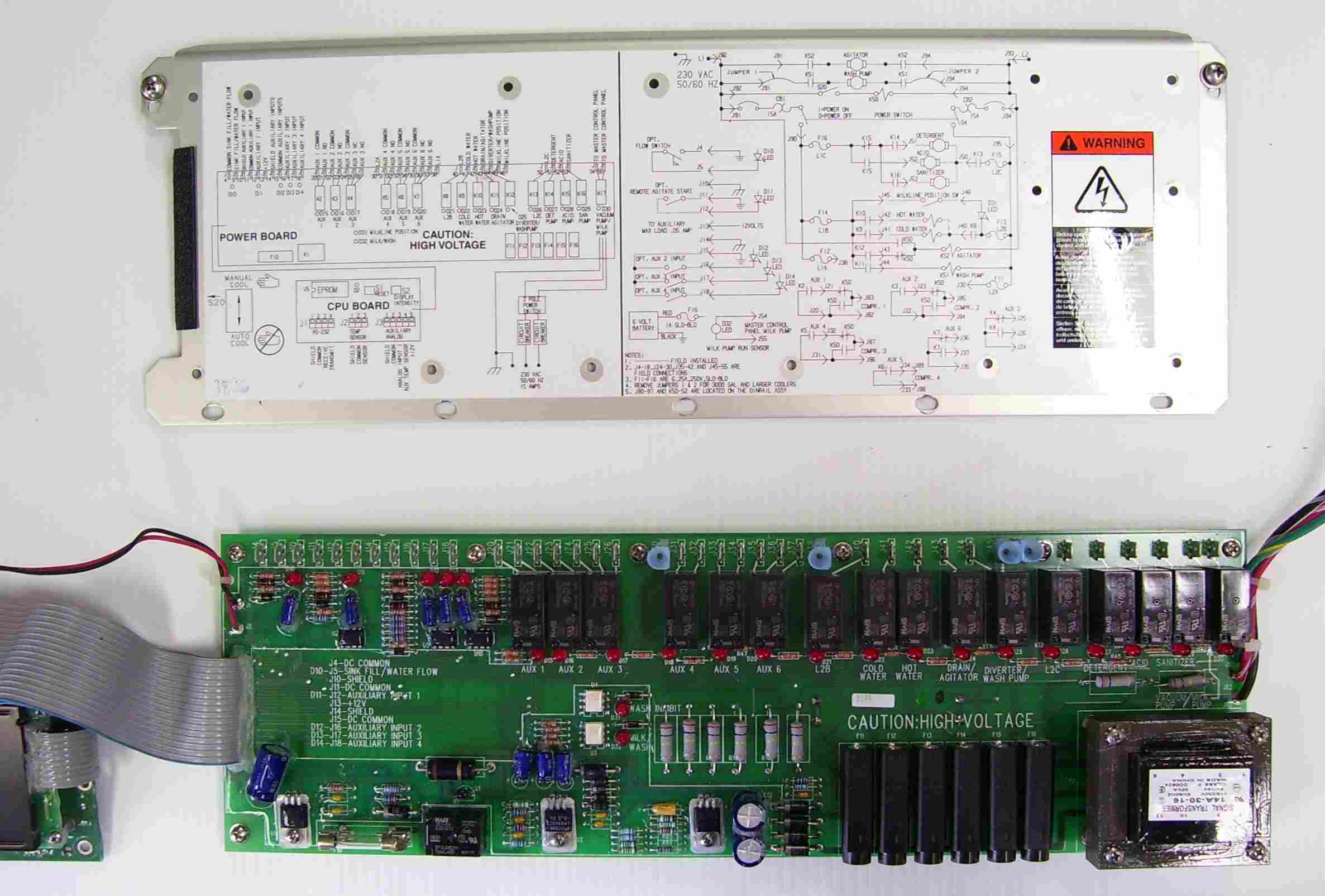

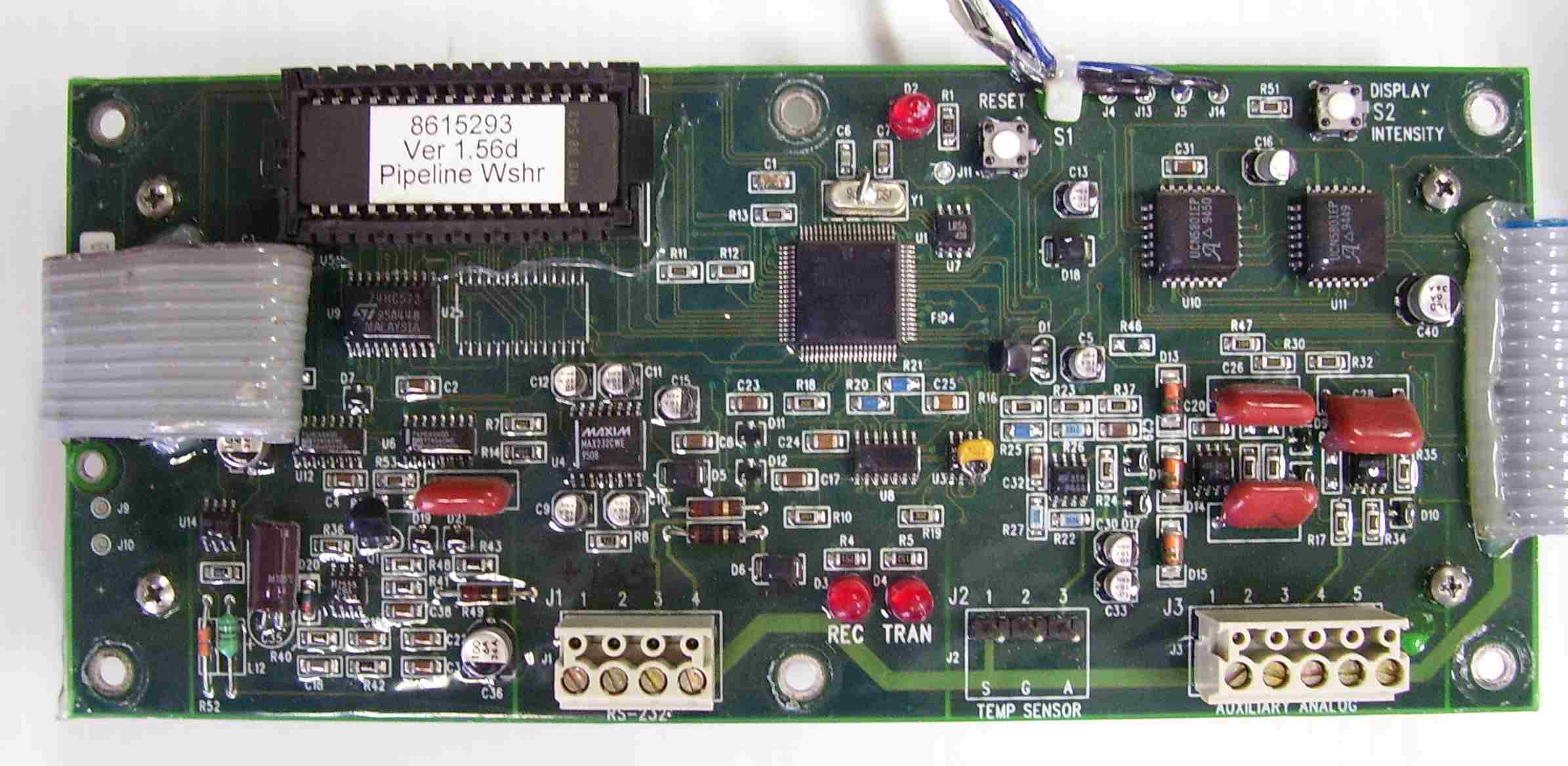

Guardian II Pipeline Washer

Guardian-II Control PCB and Mounting Plate

This device is a programmable electronic milk-pipeline washer consisting of 2 modules.

It has one module for the control electronics ... the digital display screen ... and the programming buttons ...

... and the other ... for 3 dosing pumps that are used to dispense washing chemicals (alkaline, chlorinated, acid) ... to automatically wash the dairy milk lines.

Of the boards we have seen of this type so far ... Guardian II and Glacier-Guard ... a number have been damaged when they were run on a generator ... soooo..... if you ever need to run your gear on a generator ... make sure the voltage regulator is set properly ... and dont let it over-rev !!!

If you happen to have a faulty or damaged digital display ... we have located a limited source of replacements ... so give us a call ... and we can arrange to replace it.

We are also investigating the possibility of providing a back-lit panel, to light up the display properly ... so if you are having trouble reading the LCD panel ... on either the Guardian II ... or the Glacier-Guard ... contact us for further information.

If you are sending in any of these boards ... please download and print out a Repair Form ... fill it in ... and attach it to your boards. It provides details for payment ... shipping ... and details of the fault you are seeing with the board.

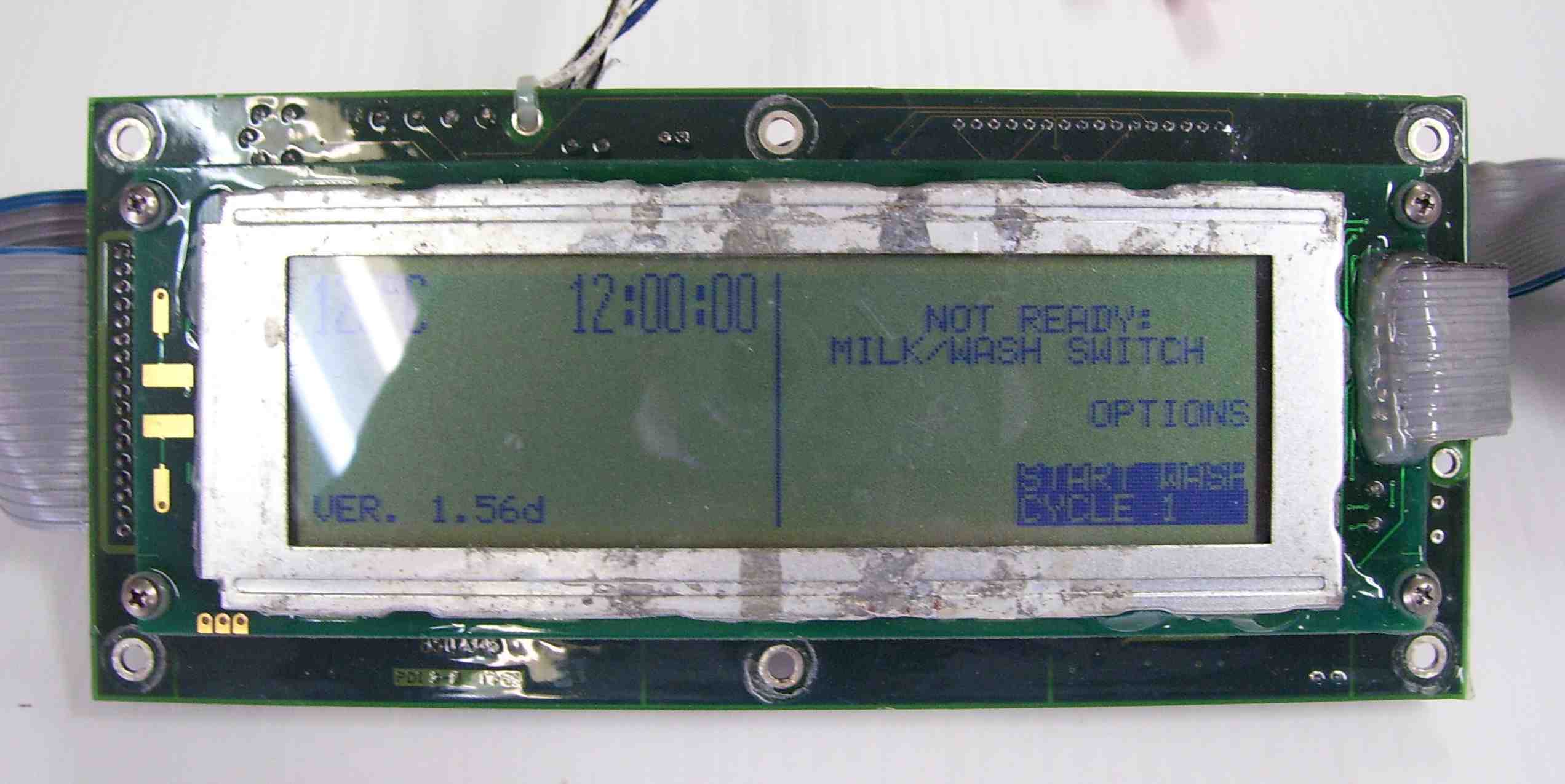

Guardian II Display Panel

Glacier-Guard Control Board

For all intents and purposes ... this board appears identical, cosmetically ... to the Guardian II board mentioned above.

The main differences are in it's internal programming ... and it's end use.

This board is designed to control the cooling of the milk tank ... and also the washing of the same tank.

It monitors and controls the temperature of the milk ... running the refrigeration compressors ... and the agitator.

Once in the wash cycle ... it controls the dispensing of chemicals and the washing of the tank.

Regarding faults with this board, and also LCD panel or back-lighting problems ... please see the notes on Guardian II boards (just above).

If you are sending in any of these boards ... please download and print out a Repair Form ... fill it in ... and attach it to your board. Again, it provides details of the fault ... and details for payment and shipping.

Glacier-Guard Display Panel

ID Controls

...

are Identification

Control

boards

...

just as the name

suggests.

They

can be

used in Herrigbone, Parallel, Rotary, Tandem and Swingover

daries.

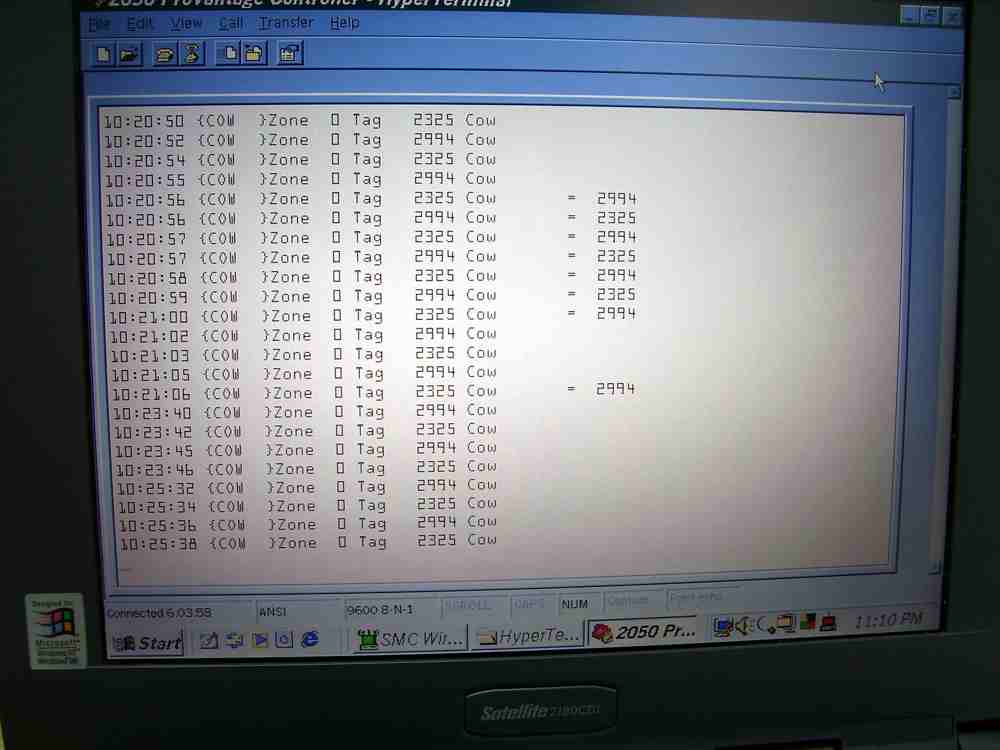

They are connected to an antenna ... that the cows walk through or past ... that constantly transmits power ... so that any identification neck tag in range (obviously worn by a cow) ... will be powered up and will then transmit back it's own unique number.

They are connected to an antenna ... that the cows walk through or past ... that constantly transmits power ... so that any identification neck tag in range (obviously worn by a cow) ... will be powered up and will then transmit back it's own unique number.

This allows data to be collected for each animal, to be used in the running and managing of the dairy ... things like milk yield recording, auto feeding, auto drafting etc etc.

The control boards have been very solidly designed and built ... to be able to run 24 / 7 year after year.

Many of them have run for 15 years plus. That's not bad ... try running your truck or your generator for 15 years straight without a break !!!

... and if one does fail, it doesn't mean it cant be repaired and put back into service.

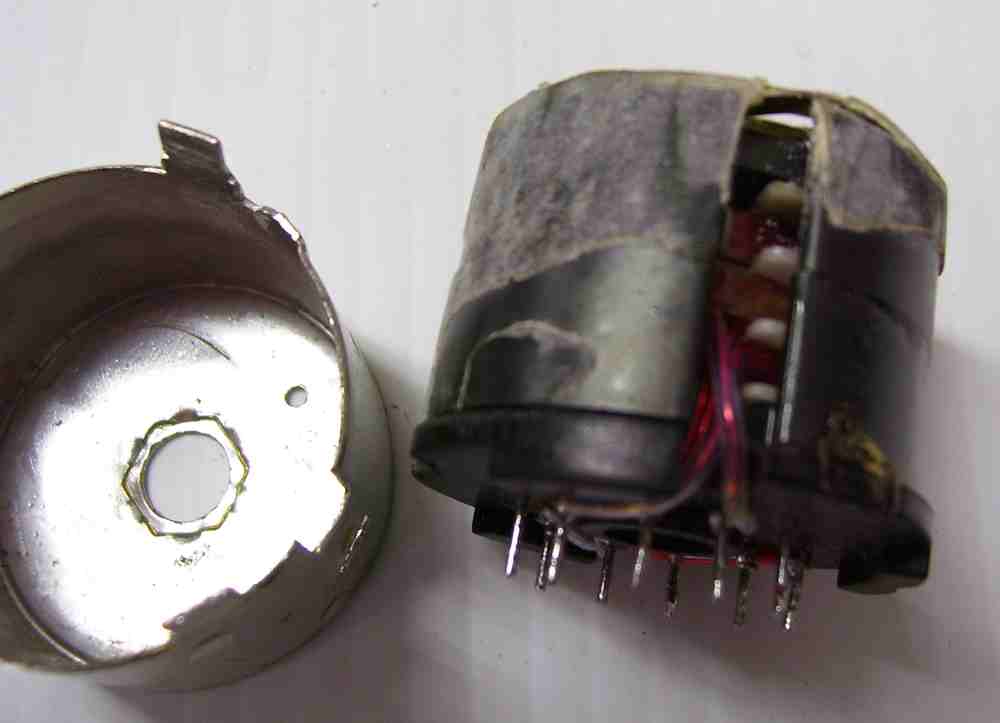

Antenna Drive Transformer and

the section of board it fits onto ...

We have repaired enough of these now to be very confident that we will be able to repair pretty much all that come in.

Several we have seen had been damaged by lightning, but were still well worth repairing and putting back in service.

It's amazing that parts are still readily available for these units too, despite having been built in the early 90's ... though not from Boumatic I might add.

We have a 'portal' antenna in the workshop along with a 2050 Network Controller, which allows us to hook up a complete system and test each unit fully once we've repaired any faults.

The ID controls can then be sent back with confidence knowing they work the way they are supposed to.

It's always good to receive this sort of equipment in batches ... as setting up the test equipment and going through the test procedures for each type can be quite time consuming.

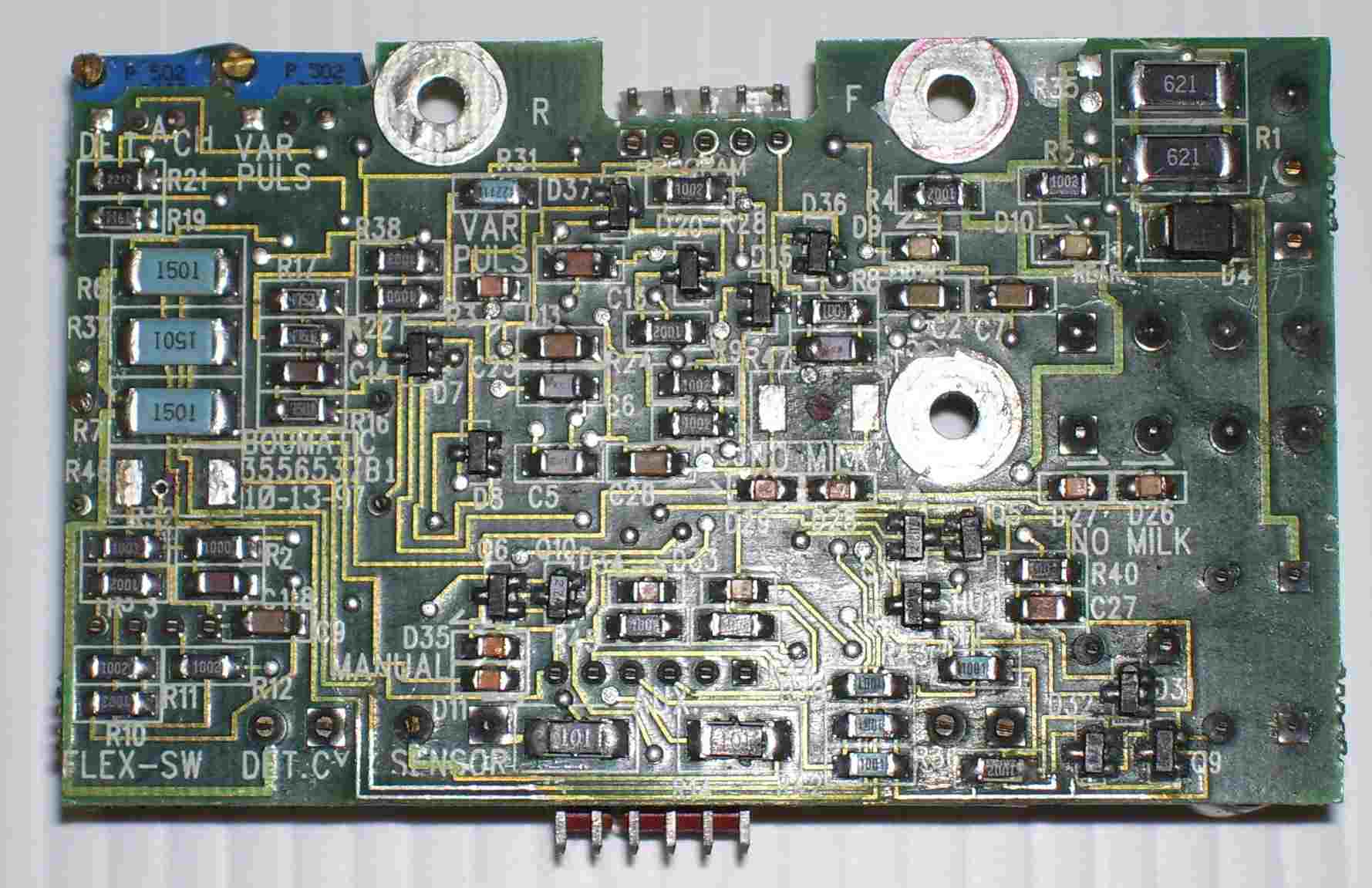

Feeder Controls

A Feeder Control with protective cover removed showing the antenna. The pcb which is almost the same size, is mounted directly below.

A pair of cow ID neck tags are resting on top. These are the same tags used on the rotary platform to 'tell' the system what position it is in at any given time.

Feeder Control units are used to provide feedback to the Network Controller to identify where the rotary platform is in relation to it's stalls.

The same ID neck tags that are used for the cows are mounted on the rotary platform, one ber bail ... and as the platform rotates, each tag tells the system where the platform is at any given time.

That enables an auto feeding system to drop feed into the correct bail ... in the correct portion size ... for the specific cow in the bail.

As the tags move relatively slowly, and pass within a few centimeters of the antenna mounted on the front of the feeder control, the antenna doesn't need to be very large, and in fact is only about 8" by 10" ... where-as the portal antennas are about 6'6" high by about 3' wide.

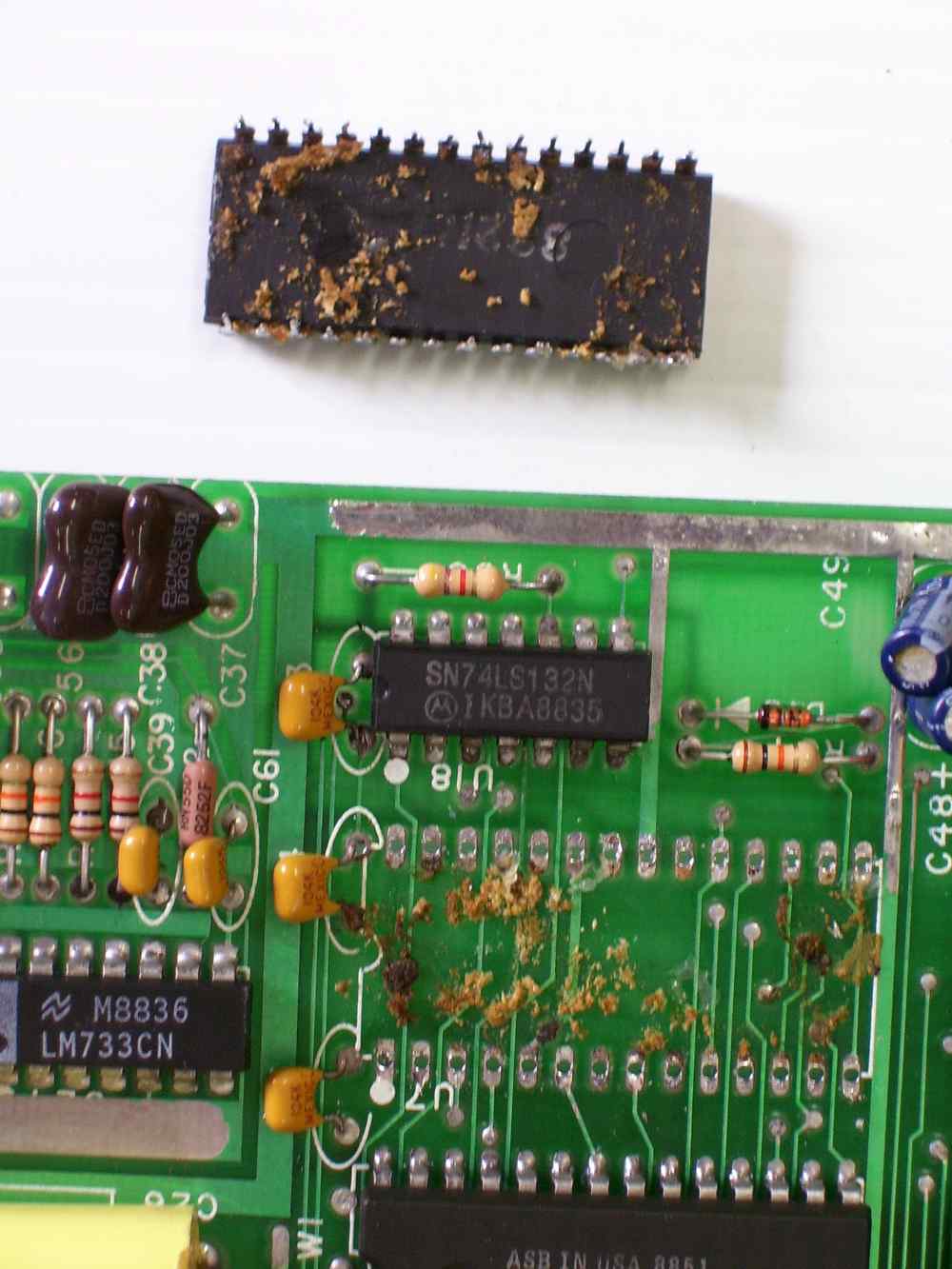

Here you can see a feeder board that has had some sort of spillage. In the photo on the left, it has had about half of the rubbish removed.

The photo on the right (bit out of focus, sorry) shows it all cleaned up.

It was only some time later that we discovered that the 'grot' had seeped in under all the IC's, so that meant removing all of them !!! and cleaning up the mess.

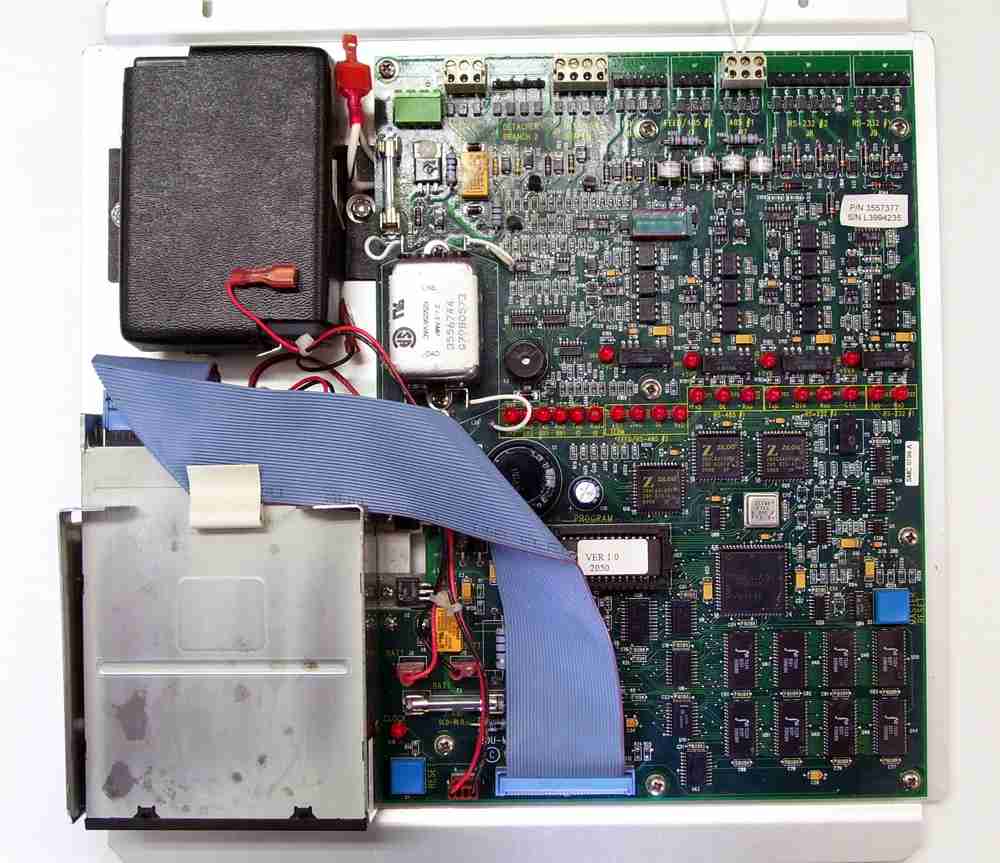

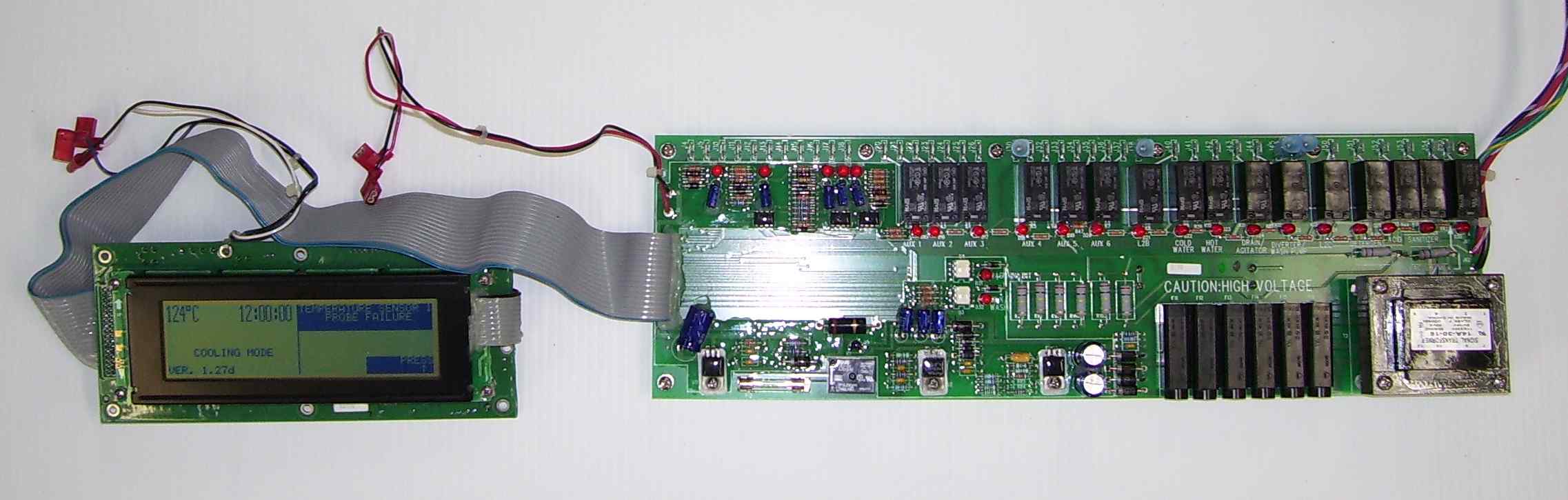

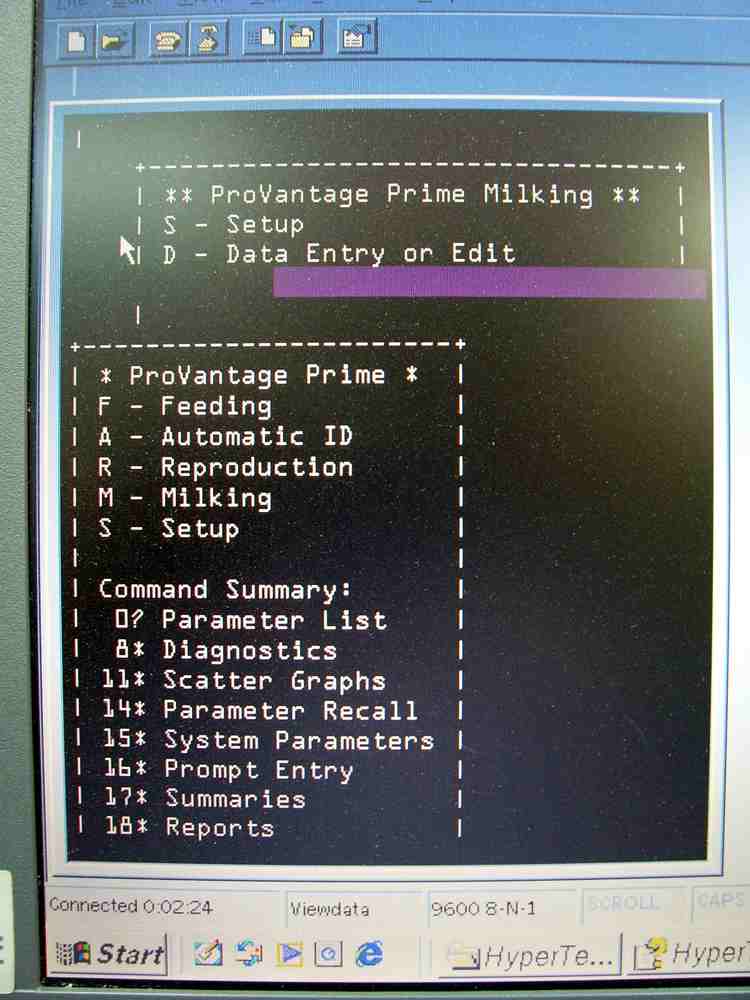

2050 Network Controller

The 2050 Network Controller is the main control unit for a dairy using the sort of gear shown above ... 3400 or 4600 detachers, Prism pulsation controllers, ID and Feeder controls or Sort Gate controls etc etc.

All of these devices feed in to it and provide the information for it to monitor milk yield ... individual feeding ... cow traffic ...

It is really just a basic computer ... and is usually connected to a terminal (screen plus a keyboard) or in some cases a normal PC ... along with a printer to provide reports.

It would certainly be regarded as old technology nowadays ... with it's floppy disks for data storage and back-up ... but it has proven to be a solid reliable workhorse for many years.

We have seen several of these which have been repaired ok ... which was just as well for their owners because a figure of approx $14,000 was mentioned as a replacement cost ...

A couple of screenshots of a PC monitoring the 2050.

There's no 'Windows' here ... this is in DOS !!!

Here's an 'interesting' one we got to work on ... no prizes for guessing what caused this damage.

... and a closeup of the bottom right corner.

(click on any of these photos for an enlargement)

Here's a photo of the same 2050 ... once repaired.

The only evidence of the damage are the stains on the top of the floppy drive unit (bottom left hand corner).

This is really a testamont to the quality of the build of these units and the protective coating over all the boards that Boumatic build.

A household PC or any normal electronics wouldn't have survived even 5% of the c&@p that was thrown at this one. :)

The coating is an absolute pain to work with ... measuring components and trying to resolder through ... but I think these photos are proof that the stuff works superbly even in the worst of environments.

We are able to renew this coating on the areas we work on, to provide continued long term protection for the electronics.

Copyright

2008 - 2021 boumaticboardrepairs.com.au / dairycircuitboardrepairs.com.au